Selecting the right Flexible PVC Profile Extrusion Machine is a critical investment that directly impacts your production efficiency, product quality, and long-term profitability. Whether you're manufacturing seals, gaskets, trim, or specialized custom profiles, the wrong machine can lead to costly downtime, material waste, and subpar outputs. This comprehensive guide will walk you through the key factors to consider, ensuring you make an informed decision tailored to your specific needs.

1. Define Your Product Requirements with Precision

The machine must serve your product, not the other way around. Begin with a crystal-clear definition of your end product.

Profile Dimensions & Complexity: Precisely determine the cross-section size, wall thickness, and geometric complexity of your PVC profile. A simple solid seal requires a different extrusion system than a multi-chamber, thin-walled trim profile.

Material Formulation & Flexibility: Flexible PVC compounds vary. Specify the Shore hardness (e.g., 60A to 90A), required flexibility, and whether your recipe includes specific additives (like plasticizers, stabilizers, or fillers). The extruder must provide gentle yet consistent processing to avoid degrading these formulations.

Output Capacity (kg/hr): Calculate your required annual or monthly production volume. Translate this into required hourly output. This will be the primary driver for determining extruder size (screw diameter) and downstream equipment speed.

2. Analyze the Core Component: The Extruder

The extruder is the heart of your production line. Key specifications here are non-negotiable.

Screw Diameter (D) and L/D Ratio: The screw diameter (e.g., 45mm, 65mm, 90mm) broadly correlates with output capacity. More critically, the Length-to-Diameter ratio (e.g., 30:1, 32:1) is paramount for flexible PVC. A longer barrel (higher L/D) ensures better melting, homogenization of the plasticizer-rich compound, and stable extrusion pressure—essential for consistent profile quality.

Screw Design & Material: The screw must be purpose-built for flexible PVC. A typical design includes a gradual compression zone and special mixing elements. It should be crafted from nitrided or bi-metallic alloys for wear and corrosion resistance against plasticizers.

Drive Power & Control: Ensure the motor provides ample, consistent torque at the required screw speed. Modern AC variable frequency drives with precise digital control are essential for maintaining stable temperatures and output rates.

3. Evaluate the Downstream Equipment

The profile takes its final shape and properties after leaving the die. Do not neglect this section.Die

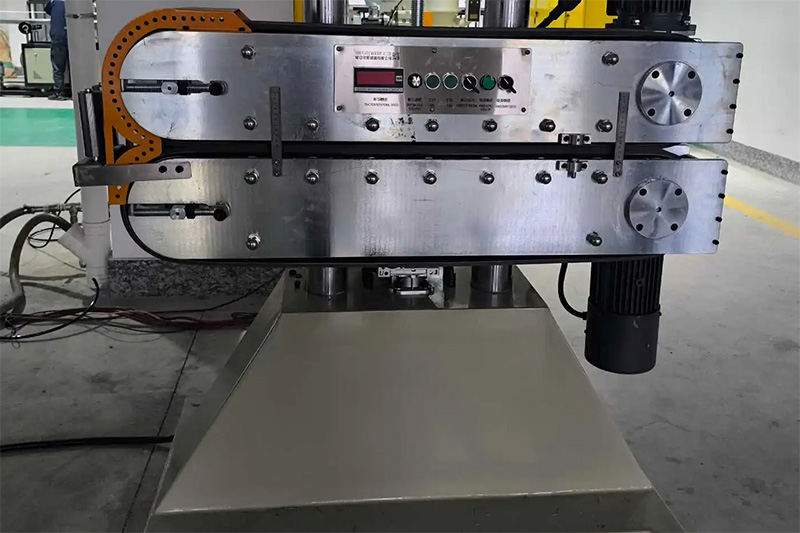

Design & Calibration: The extrusion die must be precision-machined for your specific profile geometry. Immediately after the die, the vacuum calibration tank uses precise cooling and suction to solidify the profile into its exact final dimensions. The quality of this system dictates dimensional accuracy and surface finish.

Pulling & Cutting Equipment: The puller must provide smooth, unwavering tension to prevent deformation. A traveling cut-off saw should deliver clean, burr-free cuts at precise lengths. For coiling applications, a capable coiler with adjustable tension is vital.

4. Scrutinize the Control System & Energy Efficiency

This is the brain of your operation and a major factor in long-term costs.

Digital Control & Monitoring: A modern, user-friendly PLC (Programmable Logic Controller) touchscreen interface is essential. It should allow for precise control and logging of all barrel zone temperatures, screw speed, haul-off speed, and water cooling temperatures. Data tracking aids in troubleshooting and repeatability.

Heating & Cooling Efficiency: Look for ceramic or aluminum band heaters with high efficiency. A closed-loop water cooling system for the barrel and calibration tank is crucial for temperature stability and significant water savings compared to open systems.

Overall Energy Consumption: Inquire about the energy efficiency ratings of the main drive motor, heaters, and pumps. A slightly higher initial investment in an efficient machine can lead to substantial savings over its lifetime.

5. Prioritize Manufacturer Support & Service

The best machine is only as good as the support behind it.

Technical Expertise & Reputation: Research the manufacturer's history and specialization. Do they have proven experience with flexible PVC profiles? Request case studies or client references.

After-Sales Service Package: Clarify what is included: installation supervision, operator training, warranty length and terms, and the availability of spare parts. Ask about their average response time for technical support.

Availability of Customization & Future Upgrades: Your needs may evolve. Choose a manufacturer capable of offering tailored solutions and accommodating future upgrades to the line.