Plastic profiles are rapidly breaking through traditional perceptions at an astonishing pace, expanding from basic applications like ceiling and door/window sealing strips to core areas such as wall decoration, integrated furniture, and smart home integration systems. Driven by both technological innovation and sustainability demands, this quiet material revolution is redefining the form and texture of our living spaces.

01 Evolutionary Trends: From Basic Function to the Fusion of Aesthetics and Intelligence

Modern minimalist home design pursues a balance between function and aesthetics, providing an ideal stage for the innovative application of plastic profiles.

Plastic has long shed its stereotype as a "cheap substitute." Its core advantages lie in being lightweight, easily moldable, and capable of rich visual effects. Designers can leverage these properties to create smooth curves, complex geometric structures, and integrated forms that are difficult to achieve with traditional materials.

The material's color expressiveness is particularly outstanding. Plastic can present naturally pure and vivid colors, which are hard to match with most natural materials. Whether it's high-saturation accents or soft gradient effects, plastic profiles can achieve them precisely, offering infinite possibilities for personalized spatial expression.

More importantly, the tactile feel of plastic has been improved to become soft and gentle, transforming it into a friendly and pleasant material. This enhancement in sensory experience makes plastic profiles more competitive in applications requiring direct contact, such as walls and furniture.

02 Diverse Applications: Plastic Profiles Reshaping Every Dimension of Interior Space

In modern interior design, the application of plastic profiles covers almost all spatial dimensions. From structure to decoration, from fixed installations to flexible components, these materials are redefining spatial function and aesthetics in unexpected ways.

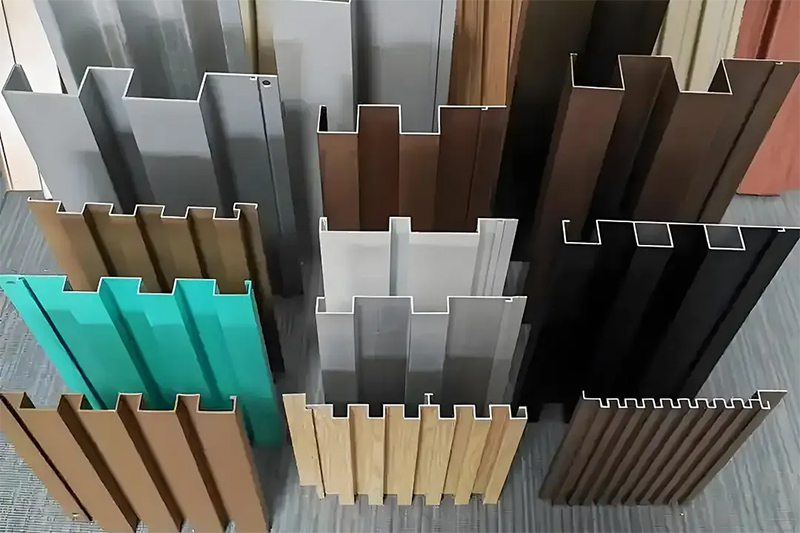

In wall systems, plastic profiles demonstrate unprecedented diversity. They can serve not only as wall panels and decorative moldings but also, by integrating lighting, acoustic adjustment, and touch functions, transform walls from passive dividers into active interactive interfaces. Specially treated PVC wall materials also offer anti-static and antibacterial effects, making them particularly suitable for spaces with high hygiene requirements.

In flooring applications, plastic profiles similarly excel. Beyond the widely known resilient flooring, modular interlocking floor systems allow users to freely combine patterns, colors, and functional zones according to their needs. These systems are lightweight and easy to install, bringing unprecedented personalization possibilities to floor design.

In the realm of furniture and custom storage, the easy workability of plastic profiles is fully utilized. Using simple tools like utility knives and tape measures, plastic sheets can be cut and assembled into storage systems that perfectly fit spatial dimensions. From kitchen drawer organizers to wardrobe modules, plastic solutions maximize the use of every inch of space, especially effective for solving storage challenges in irregular corners.

03 Creative Practice: Innovation Cases in DIY and Professional Design

The easy workability of plastic profiles stimulates creativity among both designers and ordinary users. These innovative practices demonstrate the unique value of plastics in solving specific spatial problems.

Custom containers and modular systems are star applications of plastics in home organization. For increasingly compact living spaces, plastic sheets can be made into pantry storage boxes that precisely match cabinet depths, or assembled into modular, reconfigurable wall storage systems. This "tailor-made" solution utilizes space more efficiently than standardized products.

In the field of space division and decoration, plastic profiles also perform excellently. Lightweight plastic partitions can delineate functional areas while maintaining visual transparency. Through surface treatment technologies, these partitions can mimic natural material textures or serve as multi-functional interfaces like projection screens.

Particularly noteworthy are innovative applications of plastic profiles in sustainable design. A Swiss research project successfully developed sealing profiles made from biopolymers with an organic content exceeding 40%. Their performance is close to traditional materials, and the raw materials do not come from food production. Such innovations pave the way for the eco-friendly application of plastic profiles.

04 Challenges and Responsibility: Health, Environment, and Sustainable Solutions

The widespread application of plastic profiles also brings with it significant health and environmental challenges that cannot be ignored. Acknowledging and addressing these issues is key to the industry's sustainable development.

Research indicates that phthalate plasticizers (PAEs), widely used in decorative materials, are significant indoor pollutants. PAEs can be detected in all tested materials, with the highest concentrations found in furniture panels, paints, and coatings. These chemicals may slowly release over time, affecting indoor air quality.

From a lifecycle perspective, the environmental impact of plastic building materials is even more complex. Plastic production relies on fossil fuels, and its manufacturing process is estimated to produce four times the CO2 emissions of the aviation industry. By 2050, carbon pollution from global plastic production is projected to triple.

YAOAN Wood-Plastic Composite Profile Extrusion Lines: Precision Engineering for Indoor and Outdoor Applications

YAOAN’s WPC profile Extruders are specialized systems designed to produce high-performance, eco-friendly profiles that blend polymers (PVC or PE) with wood fibers or flour. These WPC decking panel extrusion lines cater to the growing demand for sustainable, low-maintenance building materials.

Applications of Polywood wall panel extrusion line:

Construction:Decking, fencing, wall panels

Interior Design:Decorative moldings, ceiling boards

Landscaping:Garden furniture, pergolas