Triple-Layer TPU/PVC Yarn-Braided Anti-Burst High-Pressure Hose Production Line

1. Machine Overview

This integrated production line is engineered for the high-precision manufacturing of robust, multi-layer, yarn-braided high-pressure hoses. The primary application is the production of TPU (Thermoplastic Polyurethane) Anti-Burst Hoses, renowned for their exceptional pressure resistance, flexibility, abrasion resistance, and durability. A key feature of this line is its versatility, as it is also fully capable of producing PVC (Polyvinyl Chloride) Yarn-Braided Pipes with minimal adjustments. The entire system is designed with a paramount focus on dimensional accuracy and concentricity, which are critical for ensuring the final product's performance and pressure rating integrity.

2. Primary Applications

TPU Yarn-Braided High-Pressure Hoses: Used in industrial applications such as hydraulic lines (low to medium pressure), air compressor hoses, sprayer hoses, and fuel lines.

PVC Yarn-Braided Hoses: Commonly used for water discharge, agricultural sprayers, and various industrial suction and discharge applications.

3. Key Features and Advantages

Triple-Layer Co-Extrusion: Produces a hose with superior adhesion between layers, enhanced strength, and improved barrier properties.

Integrated Yarn Braiding: A in-line braiding machine applies high-tensile synthetic yarn (e.g., Polyester, Aramid) directly over the inner tube, significantly increasing the burst pressure resistance.

High Precision & Accuracy: The line is built to exceptionally tight tolerances, ensuring consistent inner diameter (ID), outer diameter (OD), and wall thickness. This is non-negotiable for achieving certified pressure ratings.

Dual Extruder & Dual Haul-Off System: Allows for independent control of different material layers and precise tension management throughout the process.

Material Versatility: Capable of processing a range of thermoplastics, including various grades of TPU and PVC.

Robust Construction: Designed for stable, continuous 24/7 operation in an industrial environment.

4. Detailed Line Configuration & Components

The production line is a sequential arrangement of the following key machines:

4.1. Extruders (Two Units)

4.2. Co-Extrusion Die Head

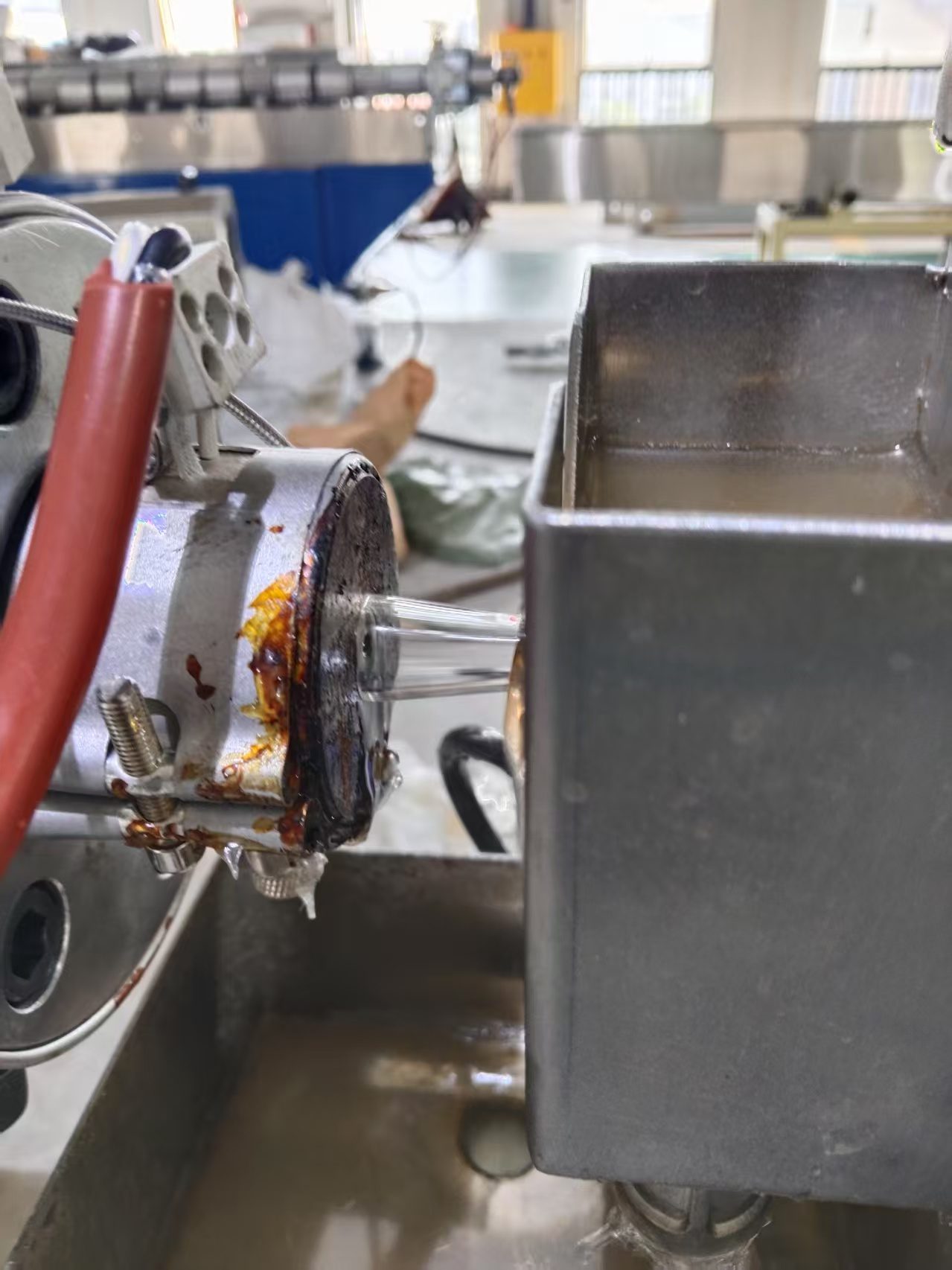

Function: The core component where the molten polymers from both extruders are combined to form the seamless, concentric triple-layer tube.

Design: A custom-designed, multi-manifold co-extrusion die.

Critical Feature: Engineered to guarantee perfect concentricity of the layers, which is directly linked to the hose's pressure performance and longevity. Adjustable flow channels ensure uniform material distribution.

4.3. Primary Cooling Water Tank (First Tank)

Function: To rapidly cool and solidify the newly extruded triple-layer tube after it exits the die head.

Design: A vacuum-controlled sizing water tank.

Process: The soft hose enters the tank and passes through a precision sizing sleeve connected to a vacuum system. This ensures the hose achieves its exact final outer diameter and a smooth, consistent surface finish.

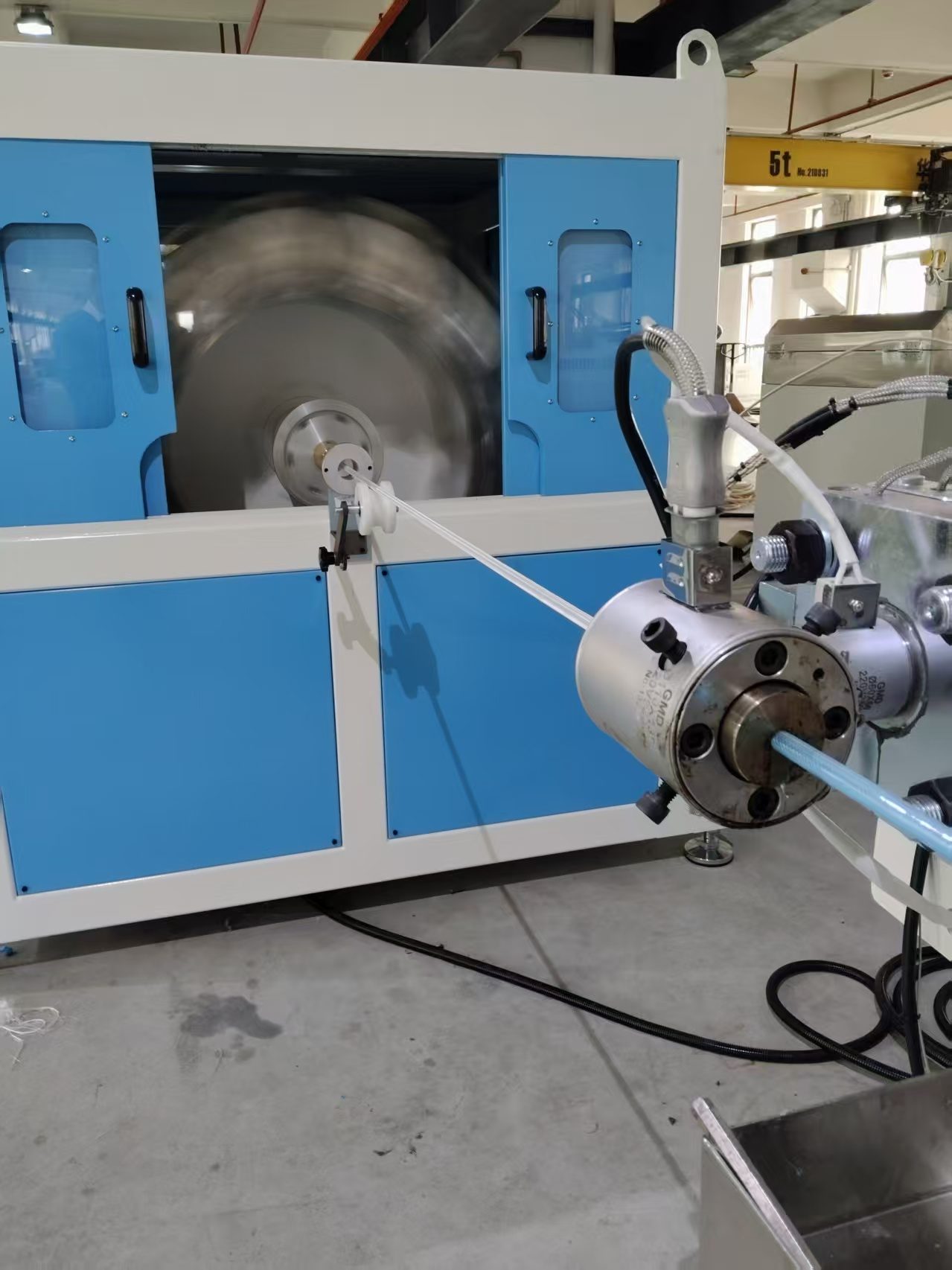

4.4. Yarn Braiding Machine

Function: To apply a braided reinforcement layer over the cooled inner tube.

Location: Positioned immediately after the first cooling tank.

Operation: The machine carries multiple spools of high-strength yarn (e.g., polyester). Carriers weave the yarn in a precise crisscross pattern (typically a 2-over-2 braid) over the tube. The braid angle and tension are critical parameters controlled to achieve the desired burst pressure.

4.5. Secondary Cooling Water Tank (Second Tank)

4.6. Haul-Off Units (Two Units)

Function: To provide the pulling force that drives the hose through the entire production line at a constant, controlled speed.

Configuration:

First Haul-Off: Located after the first water tank, it pulls the inner tube from the die head.

Second Haul-Off: Located at the end of the line, it provides the main pulling force after braiding and final cooling.

Type: Typically twin-belt caterpillar haul-offs to ensure positive, slip-free gripping without damaging the hose surface.

Synchronization: The speed of both haul-offs and the extruders are perfectly synchronized to maintain consistent wall thickness and prevent stretching or compression of the product.

5. Production Process Flow

Material Feeding: TPU or PVC pellets are fed into their respective extruders.

Plasticizing & Metering: The extruders melt, mix, and pump the polymer melt at a controlled rate.

Co-Extrusion: The melts from both extruders converge in the die head, forming a unified, concentric triple-layer tube.

Sizing & Primary Cooling: The tube enters the first water tank, where a vacuum sleeve sizes it to the precise OD and initiates cooling.

Yarn Braiding: The cooled inner tube passes through the braiding machine, where the reinforcing yarn is applied.

Final Cooling: The braided hose enters the second water tank for complete cooling.

Pulling & Winding: The caterpillar haul-offs pull the finished hose, which is then either cut to length or coiled onto a take-up reel.

6. Technical Emphasis

This machine is not a standard extrusion line. Its design and construction are heavily focused on precision engineering. The synergy between the extruders' stability, the die head's precision, the vacuum sizing system, and the synchronized haul-offs is what enables the production of high-performance, reliable anti-burst hoses that meet stringent industrial standards. The ability to process both TPU and PVC makes it a highly valuable and flexible asset for any hose manufacturer.