In the demanding world of industrial manufacturing, the true mark of excellence is not just in building superior machinery, but in engineering solutions that perfectly address the unique challenges of a specific industry. This philosophy was recently brought to life when Yaoan, a leading name in extrusion technology, successfully commissioned a fully custom-built Solid Rod Extrusion Line for a prominent player in the wastewater treatment sector. This project stands as a testament to the power of collaborative engineering and purpose-driven design.

The client, a global manufacturer of wastewater treatment systems, required high-quality, corrosion-resistant solid rods used in a critical component: the scraper mechanisms within large-scale sedimentation and clarifier tanks. These rods are the backbone of the scrapers, responsible for slowly moving along the tank to push settled sludge towards a collection hopper. The operational environment is exceptionally harsh, involving constant exposure to abrasive sludge, fluctuating pH levels, and highly corrosive chemicals.

The Yaoan Solution

Yaoan responded not with a standard catalog machine, but with a comprehensive, co-engineered solution. Our team of application engineers worked closely with the client’s technical staff to deconstruct their requirements and design a Solid Rod Extrusion Line built from the ground up for their specific application.

Key customizations of the Yaoan line included:

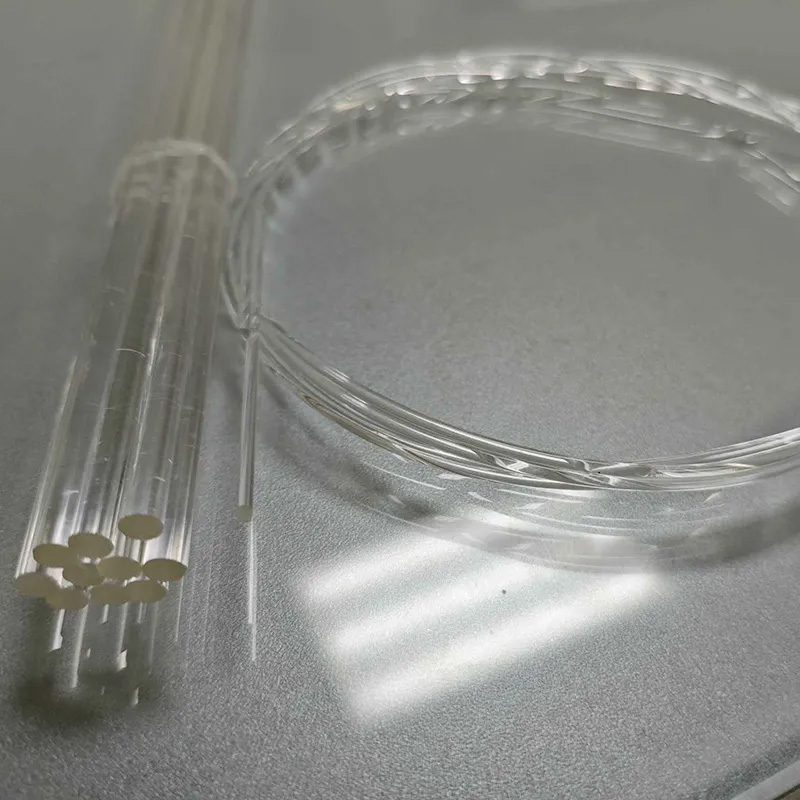

Precision Extrusion with Superior Die Technology: The heart of the line is a heavy-duty, computer-controlled extrusion press equipped with a custom-designed, multi-stage die. This die is engineered to create an exceptionally smooth surface finish, eliminating the microscopic imperfections that lead to pitting corrosion. The result is a rod with a "non-initiation" surface, significantly enhancing its longevity in corrosive environments.

In-Line Heat Treatment and Quenching: To achieve the precise mechanical strength required to withstand years of constant torque and load, the line features an integrated solutionizing and quenching system. The rod emerges from the die and immediately enters a controlled atmosphere heat treatment chamber, followed by a rapid quench. This in-line process ensures consistent metallurgical properties along the entire length of the rod, eliminating the soft spots and structural weaknesses that plagued the client's previous components.

Automated Cutting and Handling: The line culminates in a servo-driven cutting system that automatically cuts the continuous rod to the client’s exact specified lengths, complete with deburring. This minimizes manual handling, prevents surface damage, and prepares the rods for direct shipment and assembly.

The deployment of this custom Yaoan extrusion line has delivered transformative results for the client:

Dramatically Reduced Downtime: The consistency and strength of the new rods have virtually eliminated in-service failures of the scraper mechanisms. Maintenance intervals have been extended, and unplanned shutdowns are now a rarity.

Extended Component Lifespan: The superior material integrity and corrosion-resistant surface have more than doubled the service life of the rods, delivering immense long-term cost savings.

Enhanced Operational Efficiency: The perfect dimensional accuracy of the rods ensures scraper systems operate smoothly with reduced friction and lower energy consumption.

A Strengthened Supply Chain: The client has secured a reliable, in-house source for a critical component, insulating them from supply chain volatility and quality issues from external vendors.

This project for the wastewater treatment industry is a powerful example of Yaoan’s commitment to being more than just an equipment manufacturer. We are a solutions provider. By understanding the profound challenges our clients face, we can engineer extrusion lines that are not just machines, but strategic assets—driving efficiency, ensuring reliability, and building a foundation for lasting success.