PS Multiple Layers Sheet Extrusion MachineThe PS multiple layers sheet extrusion machine can make GPPS HIPS co-extrusion sheet, HIPS sheet , GPPS sheet.

we produce not only has high transparency, good barrier properties, low density, and is non-toxic and hygienic, but also can be recycled. It does not produce toxic or harmful gas when heated or burned, making it a new type of green and environmentally friendly packaging material.

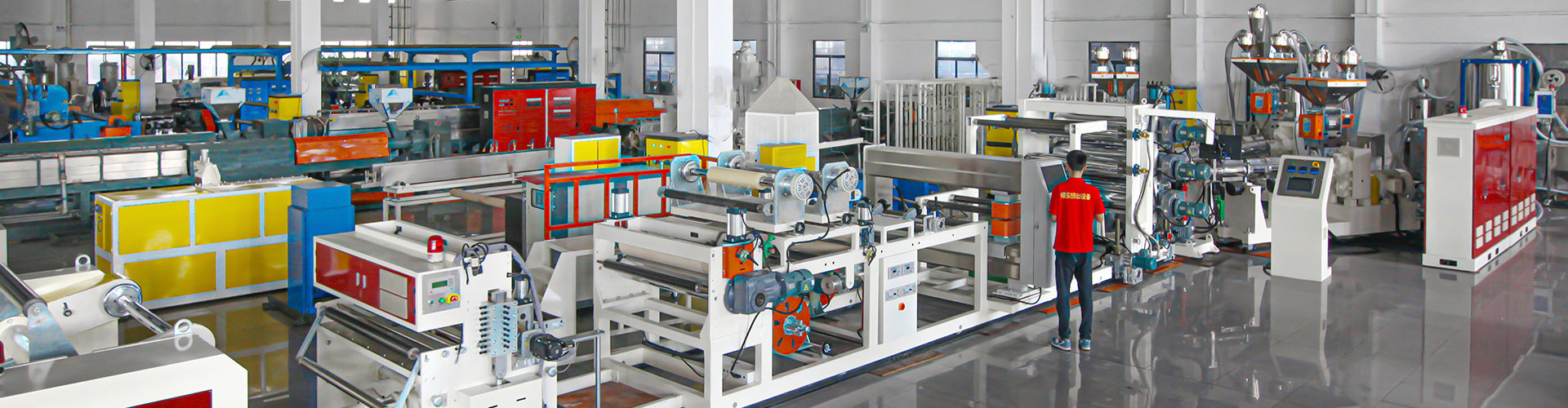

PS multi-layer sheet ExtruderHIPS GPPS refrigerator liner sheet production lineCo-extrusion PS sheet extrusion lineEmailMore