In the printing, packaging, and post-press finishing industries, film lamination is a critical process for enhancing product durability, aesthetics, and professionalism. Choosing the right equipment—automatic or manual—is a core decision that impacts production efficiency, cost control, and final product quality. This article provides an in-depth comparison of these two types of machines, helping you make an informed choice based on your specific business needs.

Automatic Film Lamination Machines: The Epitome of Efficiency and Precision

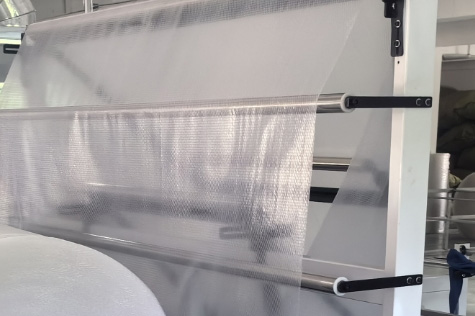

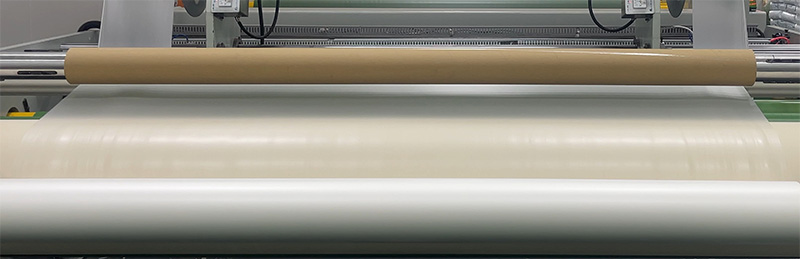

Automatic laminators utilize advanced mechanical drive systems, PLC controls, and sensors to automate the entire process from film feeding, adhesive application, and compounding to rewinding.

Core Advantages:

High Throughput & Consistency: Automatic machines typically process 20-50 meters of material per minute (speed varies by model), making them suitable for medium to high-volume orders. They ensure precise consistency in pressure, temperature, and film alignment for every item, drastically reducing human error.

Optimized Labor Costs: A single machine requires only 1-2 operators for monitoring, potentially replacing the workload of 3-5 skilled manual workers, significantly lowering long-term labor expenses.

High Material Utilization: Precise tension control and cutting systems can reduce film waste to 3-5%, compared to 8-15% common in manual operations.

Integrated Multi-Functionality: High-end automatic models often come equipped with various modules for UV coating, cold laminating, or pre-coated films, offering multiple functions in one machine.

Manual Film Lamination Machines: Flexibility and Low Barrier to Entry

Manual laminators rely on the operator for sheet feeding, alignment, and collection, usually employing pressure rollers or simple hot press methods for bonding.

Core Advantages:

Very Low Entry Cost: Basic models range from $1,000 to $5,000, making them an ideal choice for startups or small studios.

Simple, Direct Operation: Requires minimal complex training, allowing for quick handling of urgent or small-batch orders.

Unmatched Flexibility: Can readily handle various special materials, sizes, or even 3D objects with almost no setup or downtime for job changes.

Easy Maintenance: Simple mechanical structure allows users to perform most maintenance themselves.

Choose a Manual Laminator if: You are in the startup phase, handle highly diverse, low-volume orders, or have strictly limited capital.

Invest in an Automatic Laminator if: Your business focuses on standardized products, aims for scalable growth, can manage a higher initial investment, and prioritizes long-term unit cost control.

The final decision should be based on a rational analysis of your business model, growth trajectory, and resource availability. We recommend arranging equipment demos before deciding, testing with your actual materials, and collecting concrete data—from hourly output to scrap rates—as this will provide the most valuable insights for your decision.