In today's plastics processing industry, high-performance plastic sheet extruders have become the core equipment for producing high-quality plastic sheets. They not only significantly improve production efficiency but also remarkably reduce energy consumption, providing versatile solutions for various application fields through innovative extrusion technologies.

Whether for food packaging, medical devices, or industrial products, modern extrusion technology delivers benefits that meet increasingly demanding quality and environmental requirements.

The most notable advantages of modern high-performance plastic sheet extruders lie in their exceptional production efficiency and remarkable energy-saving characteristics.

The design philosophy of high-speed extrusion systems focuses on high-speed, high-output extrusion based on high quality, utilizing low-temperature plasticizing design to ensure the output of high-quality products.

Equipped with high-torque gear shafts and extra-large thrust bearings, paired with nitrided wear-resistant screws, these extruders can achieve higher output while maintaining stable operation.

Reducing energy consumption is another highlight. Advanced extruders employ screw high-frequency electromagnetic induction heating devices, effectively lowering the extruder's operating energy consumption.

Some models further reduce wear, maintenance costs, and energy use through optimized temperature control systems that combine both air and water cooling, providing more economically viable solutions for production plants.

Another major advantage of modern high-performance plastic sheet extruders is their wide material adaptability. From commodity plastics to engineering plastics, from traditional materials to eco-friendly alternatives, these extruders can handle them effectively.

Commonly processed materials include PE, PP, PVC, ABS, Polystyrene, PA, EVA, EPS, PET, PC, and bio-based materials like PLA.

To address different material characteristics, manufacturers have developed specialized models. For example, the BC 120-35-C extruder focuses on the efficient processing of PET, PLA, and their composite materials (like CPET, CPLA, GPET).

Its broad processing window adapts to different raw material grades without frequent screw/barrel or entire extruder changes, greatly enhancing production flexibility.

The high performance of modern plastic sheet extruders relies heavily on advanced control systems and intelligent technologies. These systems ensure precise control and continuous optimization of the production process.

PLC intelligent control has become the standard for high-performance extruders, enabling coordinated control between the main and auxiliary equipment.

Through the human-machine interface (HMI), operators can easily monitor processing and machine status, adjusting parameters in real-time to guarantee product quality. These intelligent control systems often feature multi-recipe memory functions, storing production parameters for different products, greatly simplifying product changeovers.

IoT-based holistic production line sensing technology has brought revolutionary advances to plastic sheet extruders.

Intelligence is also evident in temperature management. High-performance extruders are equipped with strict temperature control accuracy, combined with cooling systems that integrate both air and water cooling.

Opportunities exist everywhere: from packaging for fresh vegetables and baked goods, food display trays and party utensils, to packaging lids, medical packaging, and hardware equipment packaging.

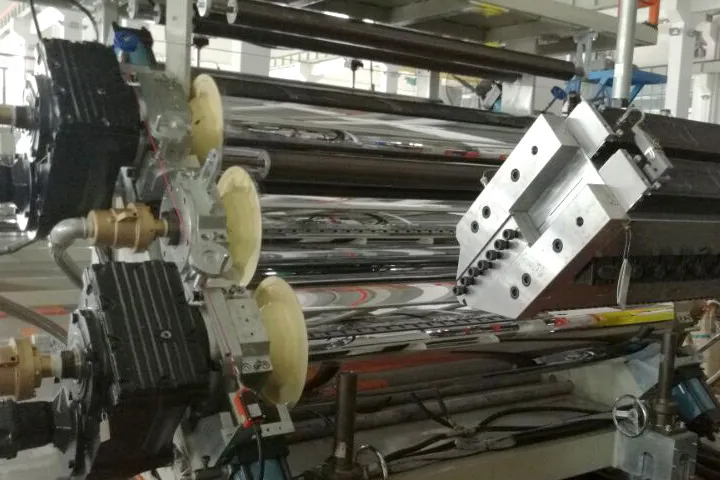

In the plastic sheet extrusion process, polymer is melted and passed through a flat die to form a molten curtain, which is drawn onto the surface of a cooling roll and immediately solidifies.

It then passes through a series of rolls that determine its thickness and texture, before having its edges trimmed and being cut to the required dimensions. These sheets are often then thermoformed into final shapes, such as interior panels for refrigerators or freezers, or plastic drink cups.

High-performance sheet extrusion systems are also widely used in processing eco-friendly materials. With growing demand for sustainable materials, extruders specifically designed for materials like PET and PLA have emerged.

The industrial sector likewise benefits from high-performance extrusion technology. The produced plastic sheets can be used to manufacture automotive components, electronic device housings, and various industrial parts.

Through multilayer co-extrusion technology, the produced sheets exhibit better barrier properties and mechanical strength, meeting the stringent material performance requirements of specific industrial applications.