Choosing a plastic roof tile machine supplier is not merely a procurement decision but a long-term investment in quality and innovation. By partnering with technologically adept and service-oriented companies, businesses can unlock new opportunities in the evolving construction materials sector. Whether you are a startup or an established manufacturer, the Yaoan will empower you to produce high-performance roofing solutions that meet the demands of modern sustainability and durability.

1.The Value of Plastic Roof Tiles in Modern Construction

Plastic roof tiles, including PVC corrugated sheets and glazed synthetic resin tiles, provide exceptional advantages for residential and commercial projects. They are weatherproof, resisting corrosion, UV radiation, and extreme temperatures. Their lightweight design simplifies transportation and installation while reducing structural load. Additionally, these tiles are eco-friendly, as they often incorporate recycled materials like PVC powders or calcium carbonate and consume fewer resources during production. With lifespans exceeding 20 years, they represent a sustainable investment for builders and homeowners alike.

2. Key Machinery for Plastic Roof Tile Production

A complete production line requires integrated equipment to ensure efficiency and consistency. Critical components include:

Extrusion Machines: Twin-screw extruders (e.g., models like SJSZ80/156 or SJZ80/156) are widely used for processing PVC powders, enabling high output rates of 300–500 kg/h.

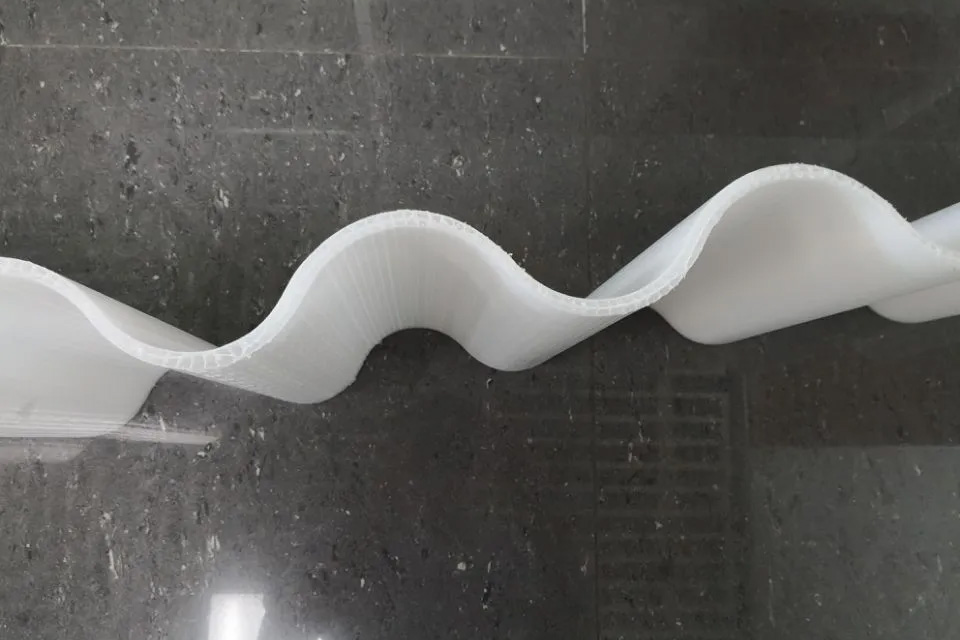

Molding and Calibration Systems: These units shape tiles into waveforms, trapezoids, or glazed designs, with precision controls for thickness (e.g., 1.5–3 mm) and width.

Auxiliary Equipment: Automated cutters, stackers, and mixers streamline processes, while co-extrusion capabilities allow for multi-layer tiles with enhanced durability.

Suppliers like Yaoan offer customizable solutions, incorporating premium components from brands such as Siemens and ABB for automation and energy efficiency

3. Traits of a Trusted Machine Supplier

When evaluating potential partners, prioritize the following attributes:

Technical Expertise and Innovation: Leading suppliers invest in R&D to optimize screw design, heating systems, and control mechanisms. For instance, Wuxi Jiahao Plastic Machinery collaborates with universities to develop eco-friendly production techniques.

Comprehensive Service Support: Reliable providers offer full lifecycle services, including installation, operator training, and troubleshooting. Qingdao Hetai Plastic Machinery ensures lifelong maintenance and remote guidance for international clients.

Quality Certifications and Customization: ISO standards and CE certifications signal compliance with international safety and performance benchmarks. The ability to tailor machines to specific tile dimensions or raw materials (e.g., using PVC blends or ASA coatings) is equally important.

Global Logistics and Communication: Suppliers with experience exporting to regions like global understand shipping complexities and provide clear contractual terms