Plastic monofilament — the slender, single-strand polymer thread — is an unsung hero in countless industries. From the bristles in your toothbrush and the fishing line in your tackle box to industrial brushes, surgical sutures, and advanced 3D printing substrates, its applications are vast and critical. At the heart of producing this versatile material lies a sophisticated and precise process: monofilament extrusion.

For manufacturers, selecting the right monofilament extrusion equipment is not just a purchase; it's a strategic investment that determines product quality, production efficiency, and long-term profitability. This guide serves as your comprehensive roadmap, detailing the essential types of equipment and providing a clear framework for making the optimal choice for your specific needs.

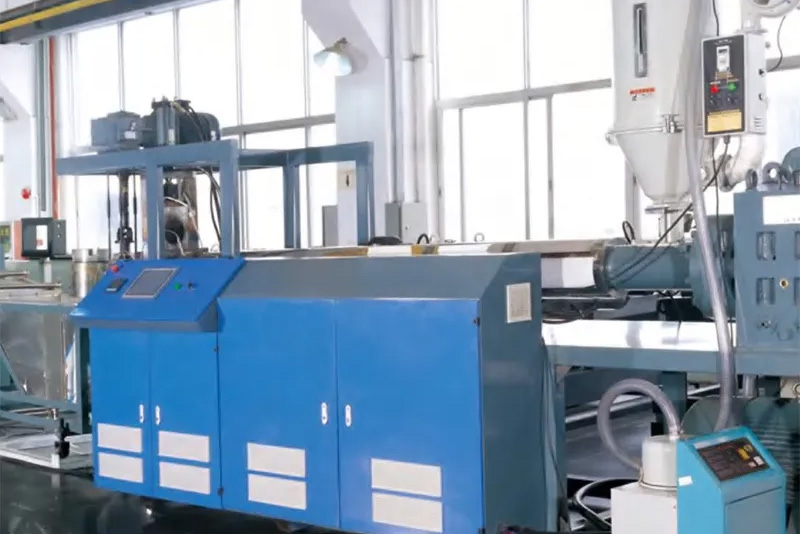

Types of Monofilament Extrusion Equipment

Systems are configured differently based on output, material, and application. Here are the primary types:

1. Standard Single-Screw Extrusion Lines

Description: The most common and versatile setup, built around a single rotating screw in a barrel. It handles a wide range of thermoplastics like PP, PA (Nylon), PET, and PE.

Best For: General-purpose monofilament production for applications like brush bristles, technical textiles, and packaging filaments. Ideal for manufacturers with diverse product needs or those entering the monofilament market.

2. Twin-Screw Extrusion Lines (Co-rotating)

Description: Features two intermeshing screws that provide superior mixing, compounding, and heat transfer.

Best For: Processing filled polymers (e.g., with additives, colors, or masterbatches), engineering plastics, or materials that require devolatilization (removal of moisture/volatiles). Excellent for consistent quality with challenging formulations.

3. High-Speed & High-Output Lines

Description: Engineered for maximum throughput, often featuring advanced screw designs, high-precision spin pumps, and multiple drawing stages with individual digital drives and tension controls. Winders are ultra-fast and automated.

Best For: Large-scale production of commodity monofilaments (e.g., for synthetic grass, industrial sewing thread) where production volume and cost-per-kilogram are paramount.

4. Precision Micro/Mono-filament Lines

Description: Designed for producing ultra-fine filaments (deniers as low as 1 or less) with extreme diameter tolerance (±1-2%). They emphasize vibration dampening, micro-filtration, and nano-precision in spinning pumps and godets.

Best For: High-tech applications such as medical textiles, optical fiber coatings, precision brushes (e.g., for electronics cleaning), and specialized filtration media.

5. Dedicated Material-Specific Systems

Description: These lines are optimized for a particular polymer family. For example:

PP/PE Lines: May have longer cooling baths due to crystallization characteristics.

Nylon (PA) Lines: Require precise humidity control and often integrated moisturizing systems post-drawing, as nylon is hygroscopic.

PET Lines: Typically feature solid-state polymerization (SSP) capabilities or specialized thermal treatment for high-tenacity industrial yarns.

How to Choose the Right Equipment – A 4-Step Framework

Step 1: Define Your End Product Precisely

This is the foundational step. Clearly specify:

Material: Which polymer(s) will you use?

Diameter & Tolerance: What is the target diameter and the allowable variation?

Tensile Strength & Elongation: What are the key mechanical properties required?

Final Application: Is it for abrasive brushes, soft-contact medical devices, or outdoor UV-exposed fencing? This dictates material grade and processing needs.

Step 2: Assess Your Production Requirements

Output (kg/hr): Determine your required throughput. Are you prototyping, running small batches, or engaged in mass production?

Line Versatility: Do you need a single line to produce multiple products (different diameters/materials), or will it be dedicated to one product? Flexibility adds complexity and cost.

Step 3: Evaluate Critical Technical Specifications

Extruder Size (Screw Diameter): Dictates throughput capacity. Common sizes range from 35mm to 90mm.

L/D Ratio of Screw: A longer barrel (e.g., 30:1 or 36:1) provides better melting, mixing, and stability, especially for temperature-sensitive polymers.

Number and Control of Drawing Stages: More stages (e.g., 3-5) allow for finer control over the drawing profile, critical for high-tenacity filaments.

Control System: Modern PLC-based systems with SCADA/HMI interfaces are essential. They provide recipe management, real-time monitoring, data logging, and diagnostic tools, ensuring repeatability and reducing human error.

Step 4: Consider Operational & Commercial Factors

Floor Space: A full line can be 20-50 meters long. Ensure your facility can accommodate it.

Energy Efficiency: Look for features like high-efficiency drives, optimized thermal insulation, and heat recovery systems. They significantly reduce long-term operating costs.

Ease of Maintenance & Service: Ask about component accessibility, spare parts availability, and technical support from the supplier. Downtime is costly.

Budget: Balance initial capital expenditure (CAPEX) with total cost of ownership (TCO), which includes energy, maintenance, and yield losses.