In modern industrial production, multifunctional plastic coating systems have emerged as a significant technology within materials engineering. By applying polymer coatings to diverse substrates, this approach creates composite materials that combine the advantages of multiple substances.

This technique not only broadens the application scope of conventional materials but also unlocks entirely new possibilities for product design.

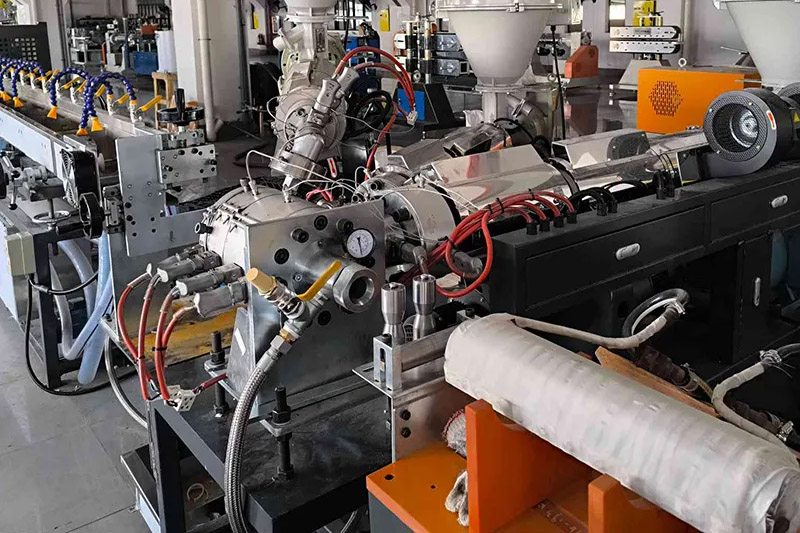

Multifunctional plastic coating systems are primarily achieved through two fundamental processes: dry lamination and hot lamination. Dry lamination involves bonding plastic films to materials such as metal foils using adhesive coating. This method allows control over the thermal shrinkage rates of different materials, minimising warping or wrinkling in the final product.

Thermal lamination, conversely, requires no adhesive. Instead, materials are heated to a molten state before being fused onto other substrates to form new composites. This method leverages the inherent properties of each material without relying on adhesives, withstanding temperatures up to 400°C and facilitating the processing of highly heat-resistant materials.

Additionally, a fused resin application process exists, wherein thermoplastic resin is heated to dissolution and directly coated onto material surfaces. This achieves high-thickness, high-precision coating (thickness accuracy within ±2%) with outstanding surface smoothness.

Plastic film substrates: Multifunctional plastic coating systems can be applied to the surfaces of various plastic films, including polyester fibre films, polyimide films, and polyvinyl chloride films. These coatings not only alter the surface properties of the film but also impart new functionalities such as conductivity, corrosion resistance, and decorative qualities.

Fabrics and Fabric Bases: Applying plastic coatings to fabric bases produces imitation leather products like artificial leather. Common methods include calendering and coating.

Calendering employs a calender to form polyvinyl chloride into film before bonding it to the substrate, whereas coating involves applying a plastic sol directly or indirectly onto the substrate. Products manufactured through these methods combine the abrasion resistance of plastics with the flexibility of textiles, finding extensive application in furniture, automotive interiors, and apparel.

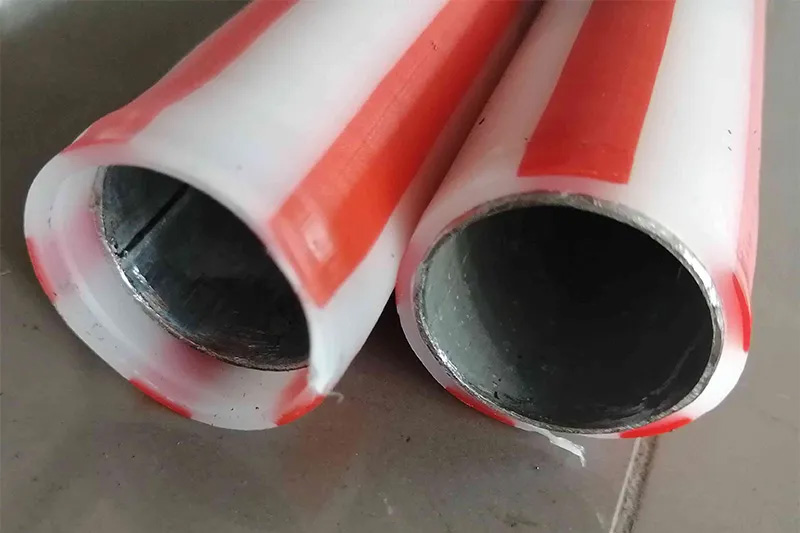

Metal substrates: Applying plastic coatings to metal surfaces preserves the inherent properties of the metal while imparting certain characteristics of plastics, such as corrosion resistance, abrasion resistance, electrical insulation, and self-lubrication.

Common metal coating techniques include flame spraying, hot-melt spraying, fluidised spraying, suspension coating, and electrostatic spraying. Laminated steel technology employs high-temperature pressing to bond plastic film to metal sheets, replacing traditional internal and external coating methods for metal plates.

Paper substrates: Plastic coatings applied to paper can produce products such as coated fabrics and plastic wallpaper. This coated paper is commonly known as art paper, with varieties including single-sided art paper, double-sided art paper, premium double-sided art paper, and high-grade snow-finish (matt) art paper. It is used for a wide range of colour printed materials.

Application Areas and Advantages

The multifunctional plastic coating system boasts an exceptionally broad range of applications, encompassing electronic components, electromagnetic shielding, vibration-damping parts, backlighting materials, flexible printed circuits (FPC), medical devices, automotive components, home building materials, and decorative materials.

The advantage of this coating system lies in its ability to organically combine the properties of different materials, creating composite performance unattainable by any single material alone. For instance, metal-plastic composites retain the strength of metal while possessing the corrosion resistance of plastic; fabric-plastic composites simultaneously offer the flexibility of fabric and the waterproofing of plastic.