We can provide customers of different extrusion capacity EVA glue stick extrusion lines as well as turnkey technical support for EVA hot glue stick. Productsare widely used in and manufacturing of electricstoys,shoes and other fields.

Introduction to Hot Melt EVA Glue Stick Extrusion Machine

1. Overview of Hot Melt EVA Glue Sticks

Hot melt EVA (Ethylene Vinyl Acetate) glue sticks are thermoplastic adhesives widely used in various industries

due to their fast bonding, strong adhesion, and environmental friendliness. They are produced through an extrusion process, which ensures consistent quality and performance.

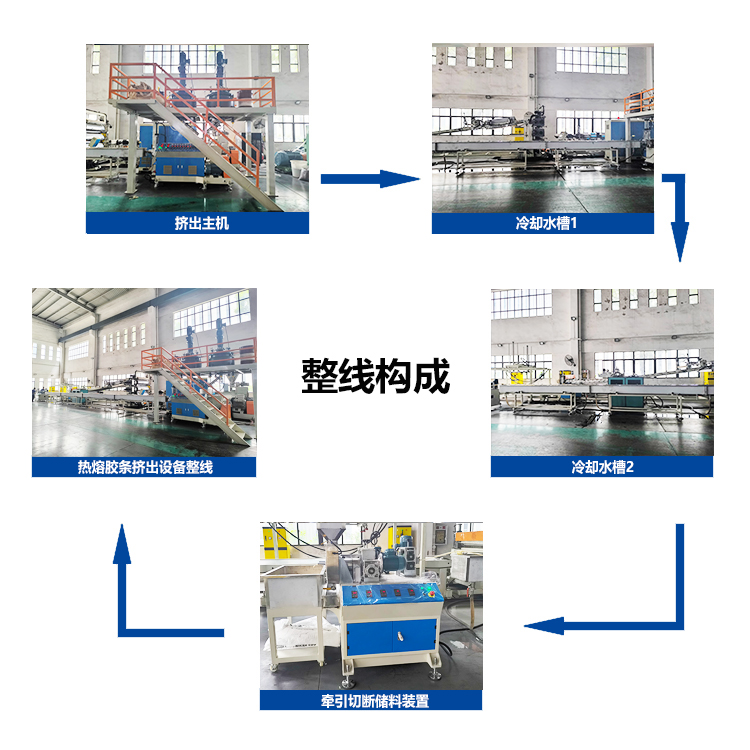

2. Key Components of an EVA Glue Stick Extrusion Line

Hot reactor: it is used to melt and blend EVA granule, Resin, Wax, additives

Extruder: The core component where EVA resin and additives are melted and mixed. Modern extruders feature precise temperature control and screw designs to ensure uniform melting and mixing .

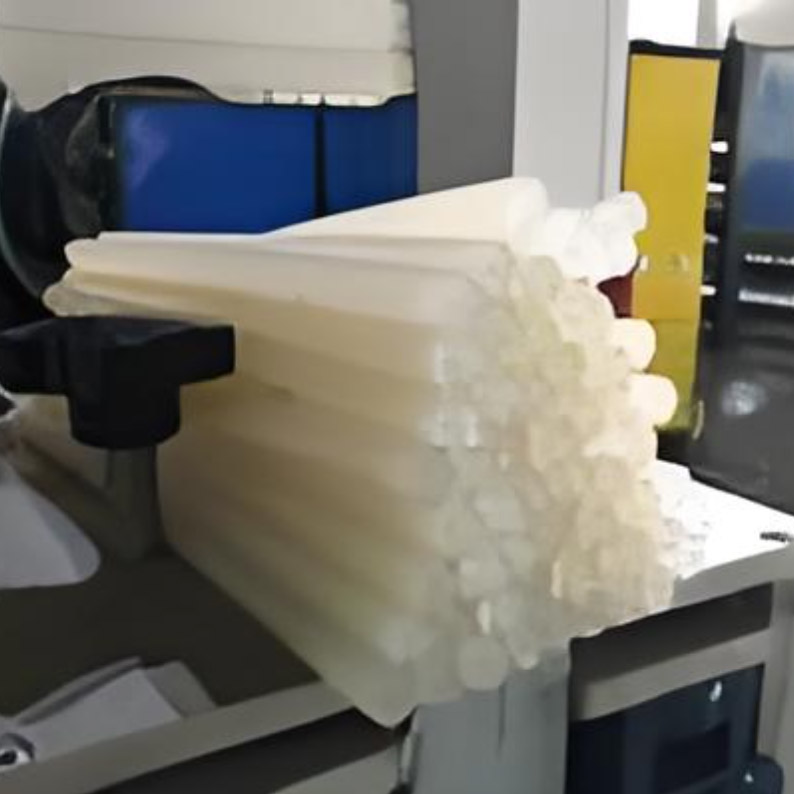

Die Head: Shapes the molten EVA into a continuous glue rod or glue stick. The die design determines the final dimensions and surface finish of the glue stick .

Cooling System: Cools the extruded glue sticks to solidify them. Water baths or air cooling systems are commonly used to achieve the desired hardness and stability .

Cutting Unit: Cuts the continuous rod into individual glue sticks of specified lengths. Precision cutting ensures uniformity and reduces waste .

3. Hot Melt EVA Glue Extrusion Machine Production Process

1. Material Preparation: EVA resin and additives (e.g., tackifiers, waxes) are blended to achieve the desired adhesive properties.

2. Extrusion: The blended material is fed into the extruder, where it is melted and homogenized. The molten material is then forced through the die head to form a continuous rod .

3. Cooling: The extruded rod passes through a cooling system to solidify.

4. Cutting and Packaging: The cooled rod is cut into individual glue sticks, which are then packaged for distribution .

Applications of EVA Glue Sticks

Packaging: Used in carton sealing, labeling, and box assembly due to their fast bonding and strong adhesion.

Furniture: Ideal for edge banding and panel bonding in furniture manufacturing .

Automotive: Used for bonding interior components and trim due to their temperature and weather resistance.

Electronics: Suitable for bonding delicate components without damaging them .

Advantages of EVA Glue Stick Extruder

- High Efficiency: Continuous production process ensures high output and consistent quality .

- Versatility: Can be customized with different additives to meet specific application requirements .

- Environmental Friendliness: Solvent-free and emits no harmful substances during use .

Glue Stick Extruder's Industry Trends and Innovations

- Customization: Increasing demand for glue sticks tailored to specific industries and applications .

- Sustainability: Development of bio-based EVA resins and recycling-friendly formulations .

- Automation: Integration of advanced control systems for precise temperature and speed regulation .

Conclusion

Hot melt EVA glue stick extrusion is a critical process for producing high-performance adhesives used across various industries.

With advancements in material science and extrusion technology, the industry is poised for continued growth and innovation.

For more detailed information, please contact me freely

Technical parameter

Model | Screw diameter(mm) | Main motor power(KW) | Traction & cutting power | Extrusion capacity (KG/HR) |

HS-65 | 65 | 5.5 | 0.75x2 | 40-80 |

HS-80 | 80 | 7.5 | 0.75x2 | 50-100 |

HS-120 | 120 | 11 | 0.75x2 | 100-150 |

| HS-150 | 150 | 30 | 0.75kwX4 | 200-250 |

HS-180 | 180 | 37 | 0.75x4 | 300-350 |

備注:非標订制、以實物爲準

Note: Non-standard machines(customized),machine outlooking subject to final machine