YAOAN's hot melt EVA glue underwater granule extrusion line

The pellet method: under water style die face cut

Extruder: Single extruder or twin screw extruder

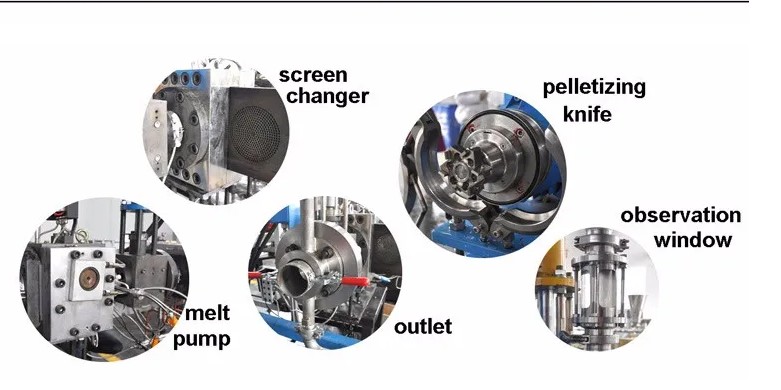

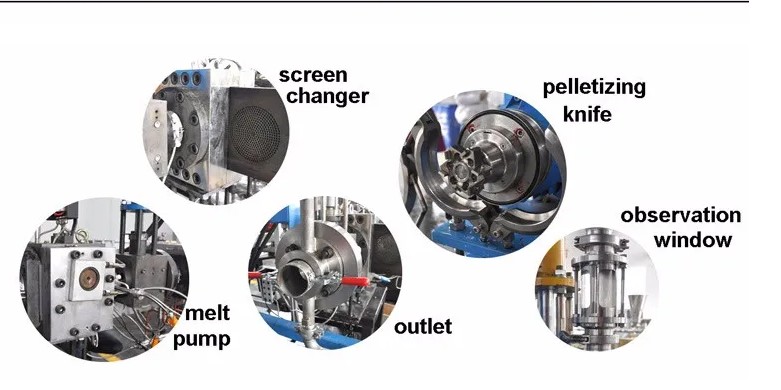

machine configuration:

Hot reactors: two

used to melt the EVA, ROSIN, Parrafin, another additives and blend them well

Extruder

extrude the melted polymer and press it out of die head

Underwater die-face-cut die head

easy accessembling, easy operation, no bridge or choke

Centrifugate dewater unit

Seperate water and pellets

Viberation sleeve: one

select the qualified pellet.

Storage Silo: one

There are different models. Pelase refer to hot melt eva glue stick machines

It is used to bean looking granule. We can provide customers of different two sets of hot glue stick mixing and extrusion system as well as turnkeytechnical support for EVA hot glue stick. Productsare widely used in and manufacturing of electricstoys, shoes and other fields.

To keep up with the development of industry related technologies, continuously improve the productivity, automatic grade of operation and minimize energy consumption of of existing glue pellet extrusion machines. Maintain an open attitude towards customer requirements and work together with them to develop glue bean extrusion machines: We can produce machines according to customer drawings and blueprints; We can work together with customers to develop new machines for their special products.

The melt glue pellet extrusion equipments cannot be allowed for shipment untill the customers confirm the result of machine test with raw material. Our staff also tests EVA melt glue granule making machines for several hours to check whether the sizes of plastic products are according to drawings, whether the ampere of motors are stable or not, whether machine runing is steady quietly., whether the machine output is up to manufacturing orders.