YAOAN'S Plastic Optical Fiber Extrusion Line is designed for the production of optical filaments through a coextrusion process. The primary structure of the filaments produced involves two key materials:

PMMA (Polymethyl Methacrylate): This material forms the middle part of the filament and is responsible for light transmission. PMMA is known for its excellent optical clarity and light-guiding properties, making it ideal for applications where light needs to be transmitted efficiently.

PVDF (Polyvinylidene Fluoride): This material is used for the outer layer of the filament and is responsible for light refraction. PVDF is chosen for its durability, chemical resistance, and ability to refract light, which helps in controlling the direction and distribution of light within the filament.

In some market variants, the middle section of the filament may be made of PS (Polystyrene) or PC (Polycarbonate) instead of PMMA. These materials offer different properties, such as varying levels of flexibility, impact resistance, and optical clarity, which can be tailored to specific application requirements.

The extrusion line comes in different configurations based on the number of cavities:

1 Cavity Style Machine: This configuration is suitable for producing a single filament at a time. It is ideal for smaller-scale production or specialized applications where precision is critical.

2 Cavity Style Machine: This configuration allows for the simultaneous production of two filaments. It is a step up in terms of production capacity and is suitable for medium-scale operations.

Multi-Cavity Style Machine: This configuration is designed for high-volume production, capable of producing multiple filaments simultaneously. It is ideal for large-scale manufacturing where efficiency and output are paramount.

Each configuration can be tailored to meet specific production needs, ensuring flexibility and scalability in the manufacturing process. The coextrusion technology ensures that the final product has the desired optical properties, durability, and performance characteristics required for various applications in industries such as lighting, medical devices, and telecommunications.

PMMA,PC,PS plastic optical fiber extrusion line 's function is to make plastic optical fiber that consists of core section of PMMA,PC or PS and surface layer of PVDF of a low refraction index.

Features of filament extrusion equipment.

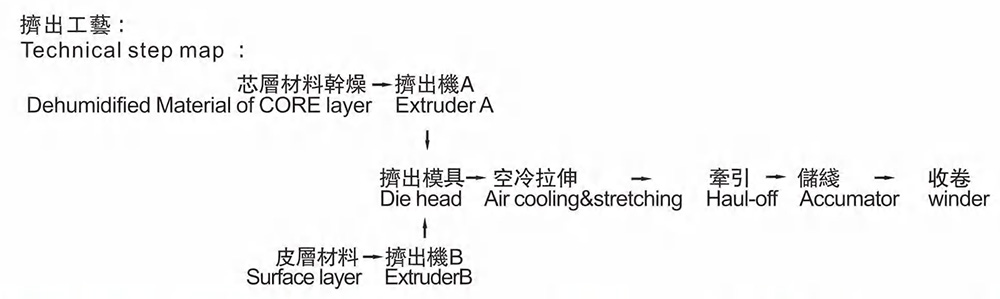

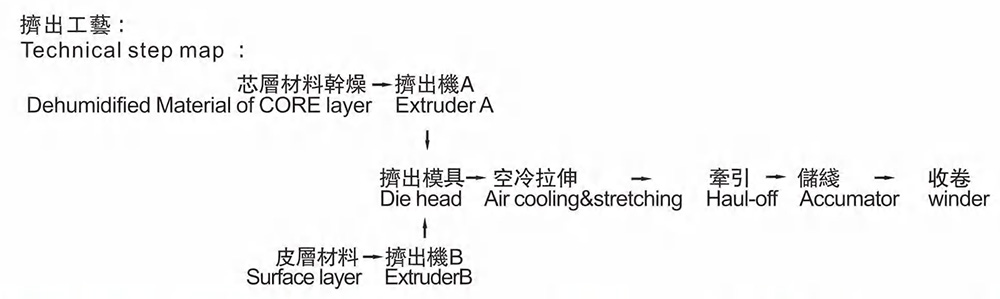

1. two extruders co-extrusion 2. those key parts as screw, barrel, co-extruison die head for PVDF are made of special steel with a strong resistance ofcorruption.

3. lt is featured with excellent plasticization , stable-extrusion, the line is under PLC control that enableeasy operation.

4. single cavity ,double cavity or multi-cavity optical fiber extrusion are available at client's request.

5. the PMMA optical filament extrusion line should work in a clean, temperaturecontrolled,enclosed workshop.

Features of PMMAoptical fiber: Big section of core layer, flexibility, easy connection, lightweight; cheap price, wide band of transition and so on.Single core or multi-core plastic optical fiber, coated withPVC or PVDF layer as sheaths; is as the media of optical transmission.

Applications of PMMAoptical fiber:It has an enormous potential market in those fields:Broadband access network system, smart home networksystems,data communication systems,inteligentsystems,industrial control systems, as well as textiles,lighting, solar energy utilization systems.