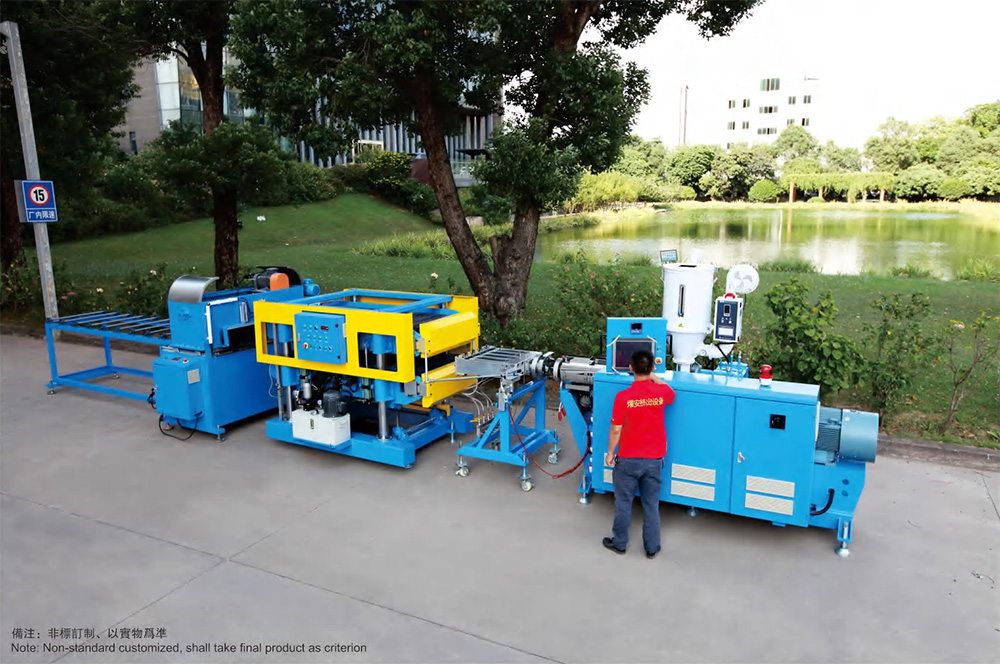

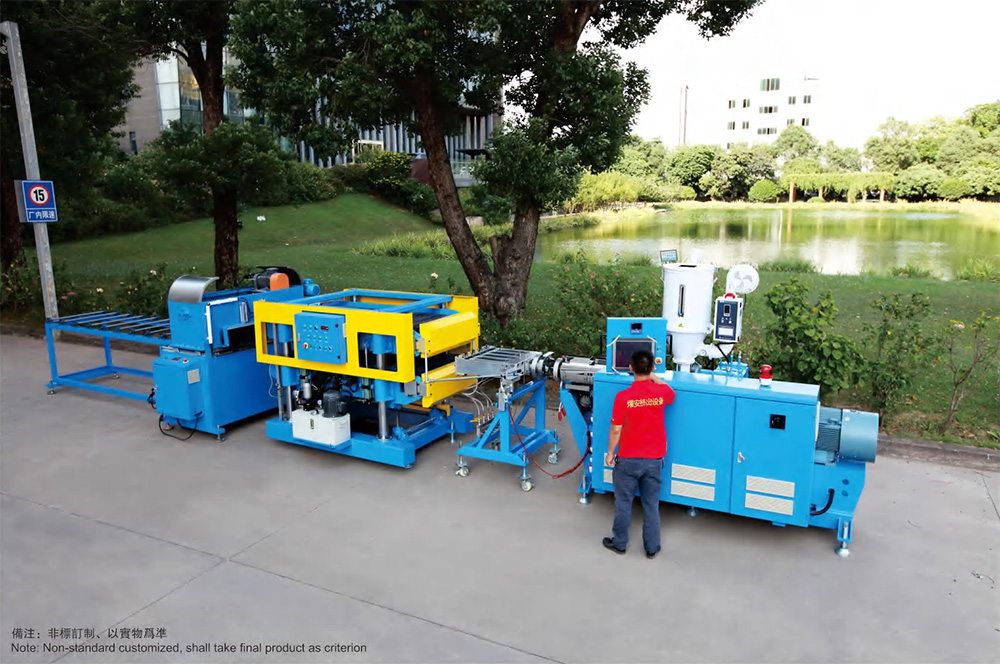

Solid Rod Extrusion Production Line Introduction

Plastic bar extrusion production line

Suitable raw materials:POM, PA,ABS, PP, PE, PVC, PEEK and other polyolefin materials

Rod diameterrange:Φ10-Φ600mm

Solid Rod Extrusion Production Line Features

1. The extruder adopts melt pressure closed-loop control to ensure the stability of melt pressure of the material, thiswould contribute to ensure the stability of productextrusion finally.

2. The rod extrusion die adopts the structure form ofheating in the front section and water coolingin the backsection to ensure the rods will be shaped well when theyleave the die.The sizing sleeve adopts the structure formofinneriacket,which can be disassembled to clean theblocked waterway.

3. The addition of a damping haul off unit can ensure theine speed ofeach rod will be consistent, avoidingscratches on the surface of the rods caused by the brakesleeve being pressed too tightly.

YAOAN' Plastic Solid Tube Extrusion Line Introduction

A Plastic Solid Tube Extrusion Line is a specialized manufacturing system designed to produce solid plastic tubes or rods of various diameters and lengths. These tubes are widely used in industries such as construction, automotive, furniture, and consumer goods. The extrusion process involves melting plastic material and shaping it into a continuous profile, which is then cooled and cut to the desired length.

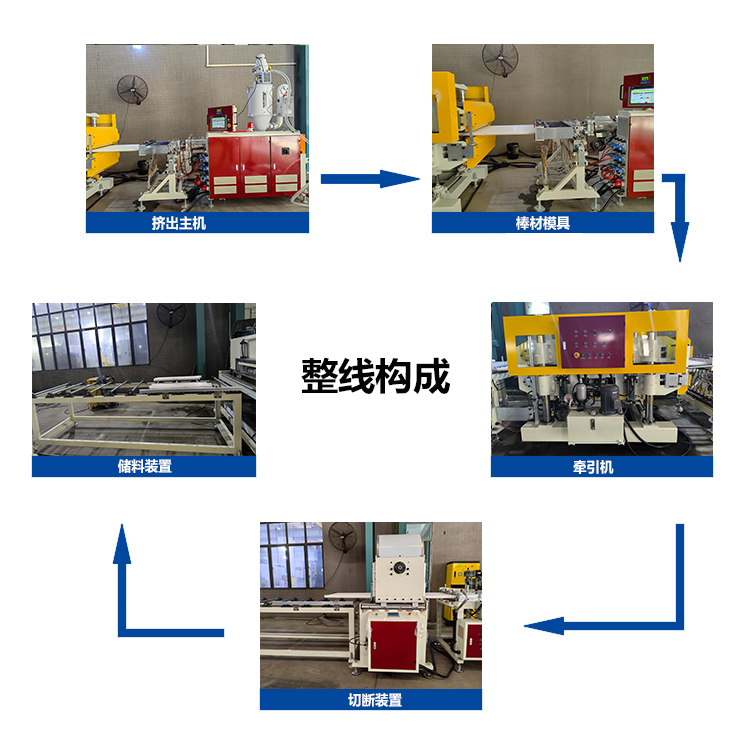

Key Components of a POM PA slid rod extrusion line

Extruder:

The heart of the extrusion line, the extruder consists of a barrel, screw, and heating elements.

Plastic raw material (in pellet or granular form) is fed into the extruder, where it is melted and homogenized.

The screw rotates to push the molten plastic through the die.

Die Head:

The die head shapes the molten plastic into the desired tube profile.

For solid tubes, the die is designed to create a solid cross-section without a hollow center.

The die head is with Cooling System:

Haul-Off Unit:

Cutting Device:

Once the tube is cooled and solidified, it is cut to the required length using a cutting device (e.g., a saw cutter).

The cutting process can be manual or automated, depending on the production scale.

Control System:

A centralized control system monitors and regulates the entire extrusion process, including temperature, speed, and pressure.

Modern PP PE slid rod extrusion lines often feature PLC (Programmable Logic Controller) systems for precision and automation.

Auxiliary Equipment:

Drying System: Pre-dries the plastic material to remove moisture, which can affect the quality of the extruded tube.such as PA, PEEK, POM, PC

Mixing Unit: Blends additives, colorants, or reinforcements with the base plastic material.

Stacker: Collects the finished tubes for packaging or further processing.

Materials Used in Solid Tube Extrusion

Common plastics used include PVC (Polyvinyl Chloride), PE (Polyethylene), PP (Polypropylene), ABS (Acrylonitrile Butadiene Styrene),PA(NYLON) and PC (Polycarbonate).

The choice of material depends on the application, as each plastic has unique properties such as strength, flexibility, and chemical resistance.

Applications of Plastic Solid Tubes

Construction: Used as structural components, dowels, or spacers.

Furniture: Legs, handles, or decorative elements.

Automotive: Rollers, guides, or protective covers.

Consumer Goods: Toys, tool handles, and household items.

Advantages of profile extrusion equipment

High Production Efficiency: Continuous process allows for large-scale production.

Customization: Tubes can be produced in various sizes, shapes, and colors.

Cost-Effective: Low material waste and energy consumption compared to other manufacturing methods.

Consistency: Uniform quality and dimensions across all produced tubes.

Conclusion

The plastic solid tube extrusion line is a versatile and efficient solution for producing high-quality solid plastic tubes. With advanced technology and automation, manufacturers can achieve precise control over the production process, ensuring consistent output for a wide range of industrial and consumer applications.