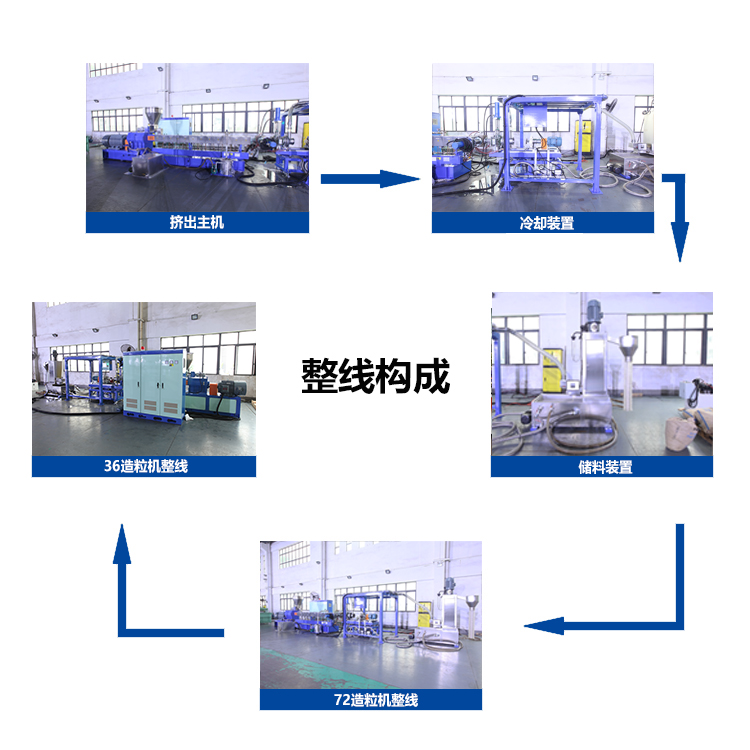

TPU under water granulation extrusion mainly consists of main extruder, sub-extruder, and accessory equipment isoften referred to as granular making Parallel twin screw TPU water granulation extrusion production line.

1.The twin screw TPU water granulation extrusion machine's main extruder is also called the first extruder ,through the screw design and change, to achievethe various requirements for plastic granular production.The main extruder is mainly composed of the following parts:Extrusion system: consists of the barrel, screw, die head and filter. lts role is to melt film, flake, powdeior other shapes of plastic materials under the action of temperature and pressure into uniform melt. Then extruded continuously from the die under fixed temperature, and constant pressure.

Transmission system: mainly consists of motor, gear reducer, belt and so on.

Heating & cooling system: mainly set up by the barrel external heaters, cooling device, and screw innercooling unit.etc.

Feeding system: mainly composed of hopper and automatic feeding device, etc.

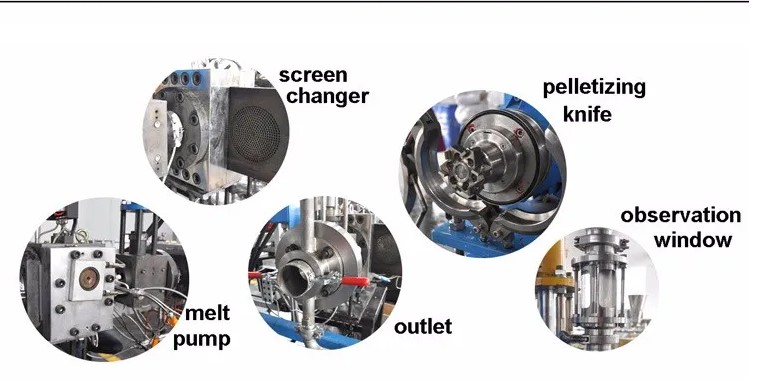

2. The sub-extruder also called the second extruder. lt's mainly used to further homogenizing anduniform extrusion materials.The differences as below:Die head. There are various types of structure; due to whether screen changer is needed.We can provide screen changer die head and non-screen changer die head.According to the screen changer shape can be divided into column and square filter die head; Accordingto filter exchange method can be divided into manual filter die head, electric filter die head anahydraulic screen changer die head; According to filter number is divided into sinale position die headand double position die head; According to granular cutting and cooling methods are divided into watercooling strand cutting, wind ring die face cutting, water ring die face cutting and water granulation.

3. The accessory equipment includes (1) cooling device (2) cutting device (3) feeding device (4) crusher(5) mixing unit (6) washing device (7)vacuum degassing device (g) drying device (9)storage silo

Technical parameter:

Model | Screw dia.(mm) | L/D | Screw speed Max.(rpm) | Power of main motor(kw) | Output(kg/h) |

AFJ-36 | 36mm | 48:1 | 600 | 37KW | 10-80 |

AFJ-52 | 52mm | 48:1 | 500 | 37-45KW | 50-200 |

AFJ-57 | 57mm | 48:1 | 400 or 500 | 37-45KW | 50-200 |

AFJ-62 | 62mm | 48:1 | 400 or 500 | 55-75KW | 80-300 |

AFJ-72 | 72mm | 48:1 | 400.500.600 | 160KW | 100-350 |

AFJ-82 | 82mm | 48:1 | 400 | 110-180KW | 200-500 |

AFJ-92 | 92mm | 48:1 | 300 or 400 | 180-220KW | 300-900 |

Afer-sales service

We provide 100% service. Bulk and customized small packaging, FOB, CIF, DDU and DDP. Let us help you find the best solution for all your concerns. We provide thoughtful pre-sales and after-sales service. We produce twin screw TPU water granulation extrusion machine that satisfy our customers and provide after-sales service including installation, startup operating extrusion machines, and personnel training.