Overview and Functionality

YAOAN's braided yarn reinforced PVC hose extrusion line is a specialized extrusion system designed for manufacturing multi-layer, high-strength PVC hoses reinforced with braided yarn. These hoses are widely used in industries such as mining, gardening, irrigation, and gas transportation due to their durability, flexibility, and pressure resistance.

Types of Yarn Braided Flexible PVC Hoses

3-Layer Style:

Outer Layer: PVC layer (provides abrasion resistance and external protection).

Middle Layer: Braided yarn layer (enhances tensile strength and pressure resistance).

Inner Layer: PVC layer (ensures smooth fluid/gas flow and chemical resistance).

5-Layer Style:

Outer Layer: PVC layer (external protection).

Second Layer: Silver-painted layer (UV resistance or aesthetic purposes).

Middle Layer: PVC layer (additional structural support).

Fourth Layer: Braided yarn layer (reinforcement for high-pressure applications).

Inner Layer: PVC layer (smooth interior for fluid/gas flow).

Color Options for Outer Layer

Single Color: One extruder for a uniform outer layer.

Dual Color: Two extruders for a two-tone outer layer.

Triple Color: Three extruders for a multi-color outer layer.

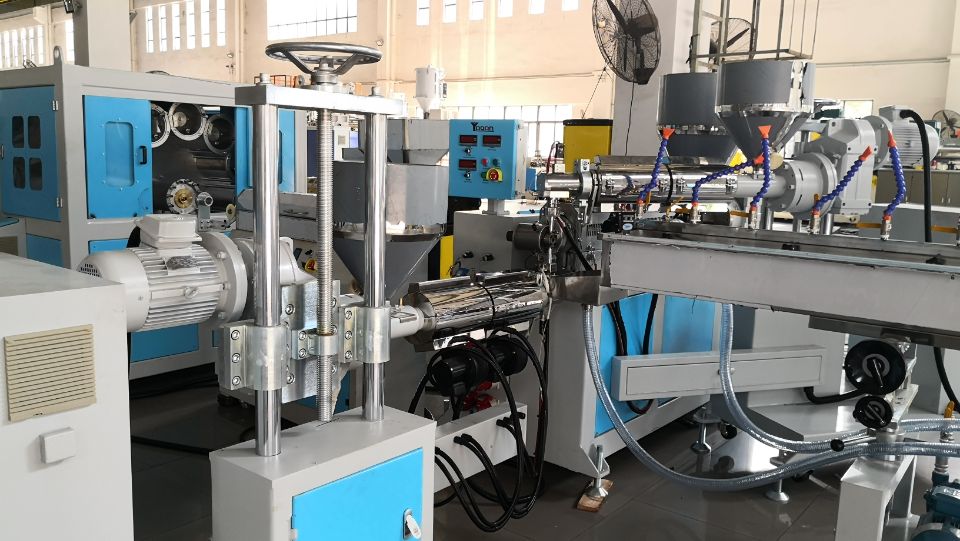

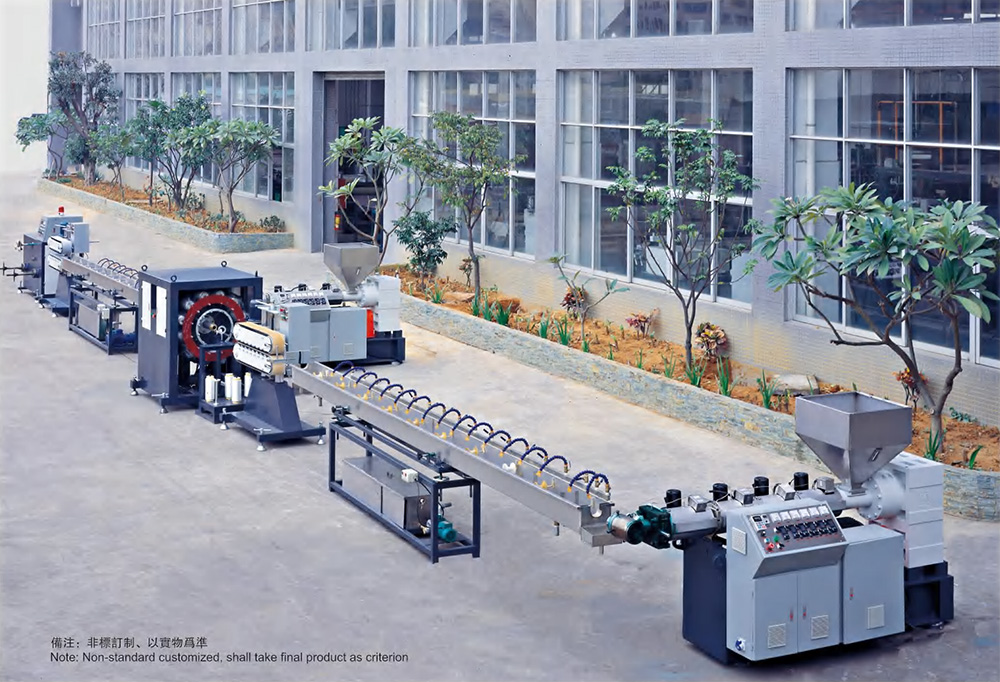

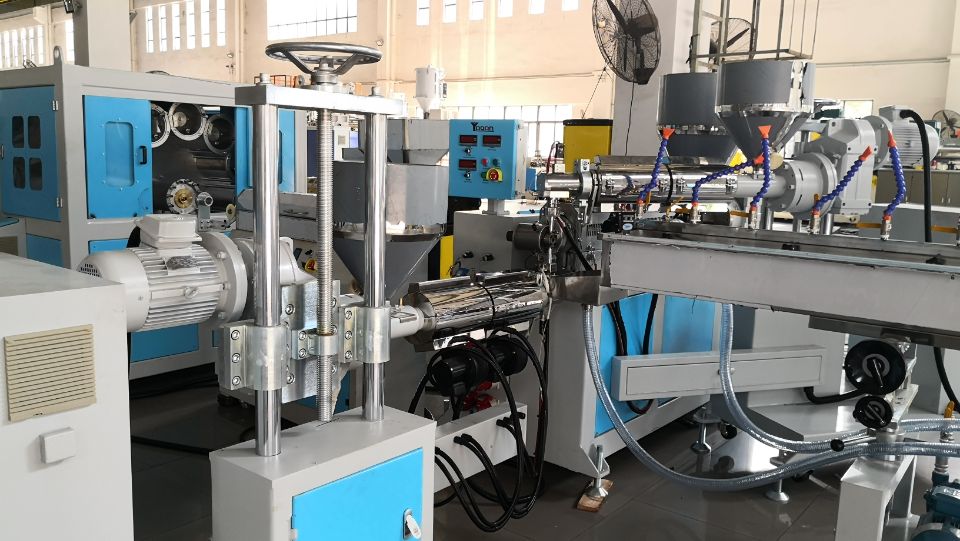

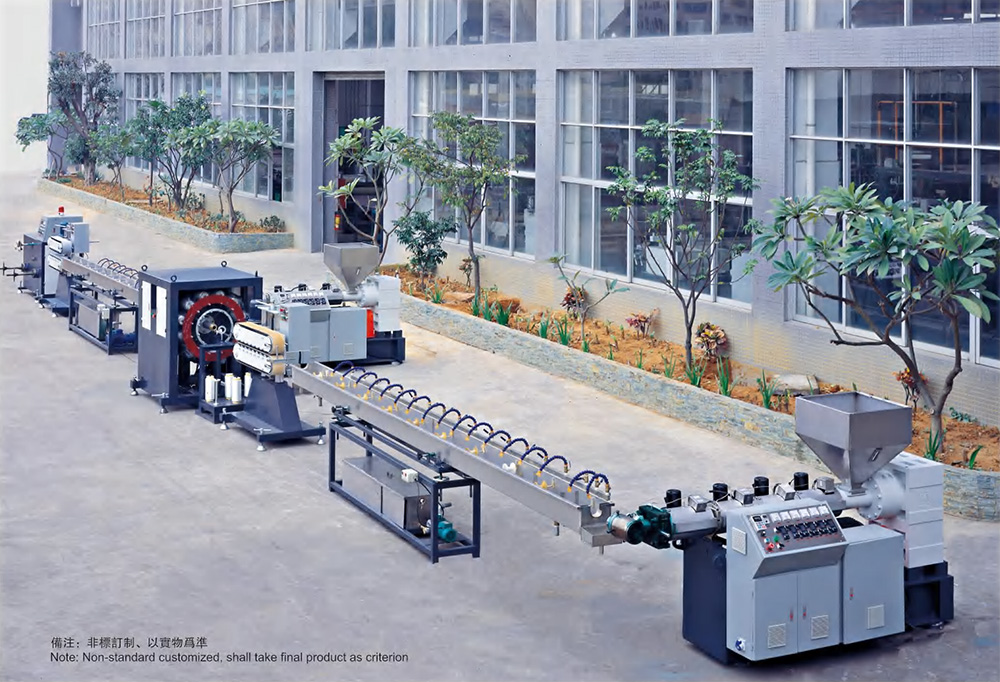

PVC braided Reinforced Pipe Extrusion Equipment Configuration for 3-Layer PVC Hose

Extruder and Die Head for Inner Layer:

A single-screw extruder processes PVC powder or granules to form the inner PVC layer.

The die head shapes the molten PVC into a tubular form.

Water Cooling Tank:

Cools the inner PVC layer to solidify its shape before braiding.

Haul-Off Unit:

Pulls the hose at a controlled speed to ensure consistent dimensions.

Yarn Braiding Machine:

Braids high-strength yarn (e.g., polyester, nylon, or aramid) around the inner PVC layer.

Maximum Speed: Up to 800 RPM for high production efficiency.

Oven:

Heats the braided layer to ensure proper adhesion with the outer PVC layer.

Extruder and Cross Die Head for Outer Layer:

A second extruder applies the outer PVC layer over the braided reinforcement.

The cross die head ensures uniform coating of the outer layer.

Water Cooling Tank:

Cools the outer PVC layer to finalize the hose structure.

Haul-Off Unit:

Pulls the finished hose for cutting or coiling.

Cutter or Coiler:

Cuts the hose to specified lengths or coils it for packaging.

Key Features of the PVC Yarn Braided Hose Exrrusion Line

Single-Screw Extruder: Compatible with both PVC powder and granules, ensuring material flexibility.

High-Speed Braiding: Up to 800 RPM for efficient yarn reinforcement.

Multi-Layer Capability: Supports 3-layer and 5-layer hose production.

Color Customization: Up to three extruders for multi-color outer layers.

Precision Control: Ensures consistent wall thickness, diameter, and braiding density.

Applications of PVC YARN Braided Hose Exrrusion Line

Gas Hoses: High-pressure resistance for LPG or natural gas transportation.

Garden Hoses: Flexible and durable for watering and irrigation.

Shower Hoses: Lightweight and kink-resistant for household use.

Industrial Hoses: Used in mining, construction, and fluid transfer applications.

Advantages of YAOAN's Garden Hose Extrusion Line

Versatility: Produces hoses for a wide range of industries and applications.

Durability: Yarn reinforcement enhances hose strength and pressure resistance.

Customization: Multiple layers, colors, and sizes to meet specific requirements.

Efficiency: High-speed braiding and automated processes reduce production time.

Ease of Operation: User-friendly design with precise control systems.

Technical Specifications of PVC Yarn Braided Hose Exrrusion Line

Extruder Type: Single-screw extruder.

Braiding Speed: Up to 800 RPM.

Hose Diameter Range: Customizable based on die head and haul-off settings.

Material Compatibility: PVC powder or granules.

Cooling System: Water cooling tanks for rapid and uniform cooling.

Why Choose YAOAN's Yarn Braided PVC Hose Machine?

Reliability: Robust construction for continuous, high-quality production.

Flexibility: Adaptable to various hose designs and materials.

Cost-Effective: Efficient production process reduces material waste and labor costs.

Technical Support: Comprehensive after-sales service and training.

This PVC braided reinforced pipe extrusion equipment is an ideal solution for manufacturers seeking to produce high-performance, yarn-reinforced PVC hoses for demanding applications. Its advanced features and customizable options make it a top choice in the industry.

Technical Parameter of Braided Yarn Reinforced PVC Hose Extrusion Line:

Model | Screw diameter | Screw L/D | Main motorpower | Braiding Power(m/c) | Yarn spool No | Capacity |

YB-50 | 50 | 28:1 | 11kw | 2.2kw | 24pcs or special requirment | 25-50kg/hr |

YB-65 | 65 | 28:1 | 18.5kw | 3.7kw | 50-90kg/hr |

YB-90 | 90 | 28:1 | 37kw | 5kw | 80-130kg/hr |