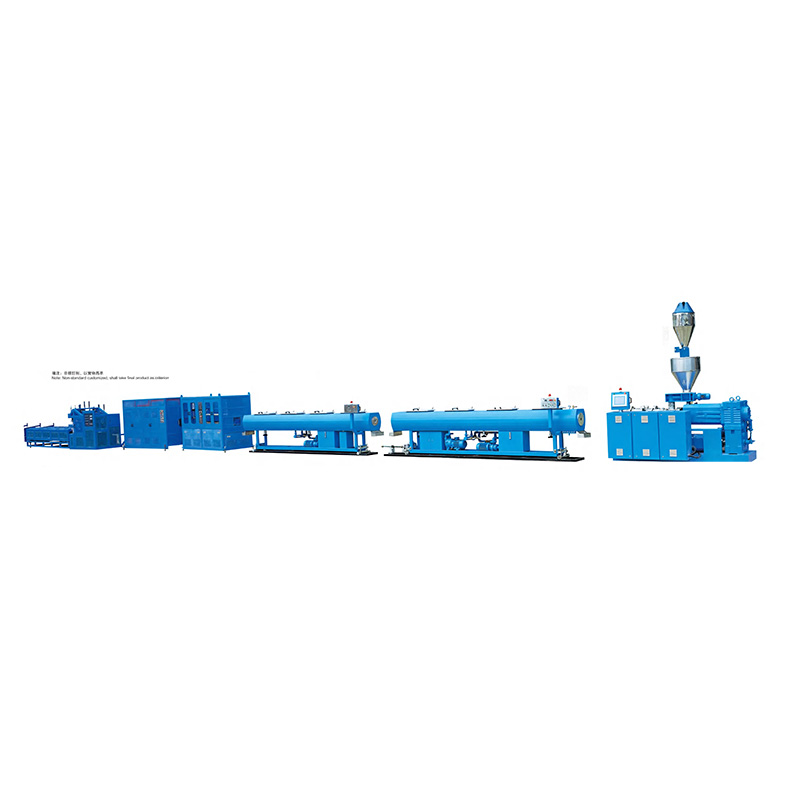

YAOAN PVC Pipe Making Machine described is a highly advanced and efficient system designed for producing a wide range of PVC pipes used in agricultural, water supply, drainage, architectural, and cable laying applications. Below is a detailed breakdown of its features, technical data, components, and functionalities:

Key Applications

Agricultural Pipes: For irrigation and water distribution.

Water Supply/Drainage Pipes: For residential, commercial, and industrial use.

Architectural Pipes: For building water supply and drainage systems.

Cable Laying Pipes: For protecting and organizing electrical and communication cables.

Technical Data

The machine is available in multiple models to accommodate different pipe diameters and production capacities:

| Model | Pipe Diameter | cavity | Extruder Model | Speed m/min | Max Capacity |

|---|

| AF63 | 16-63mm | 2 cavity | CZ55/110 | 1-10 | 120-200kg/h |

| AF160 | 75-200mm | 1 cavity | CZ65/132 | 1.5-5 | 260 kg/h |

| AF400 | 200-400mm | 1 cavity | CZ80/156 | 0.5-1.5 | 400 kg/h |

| AF630 | 400-630mm | 1 cavity | CZ92/188 | 0.1-0.8 | 650 kg/h |

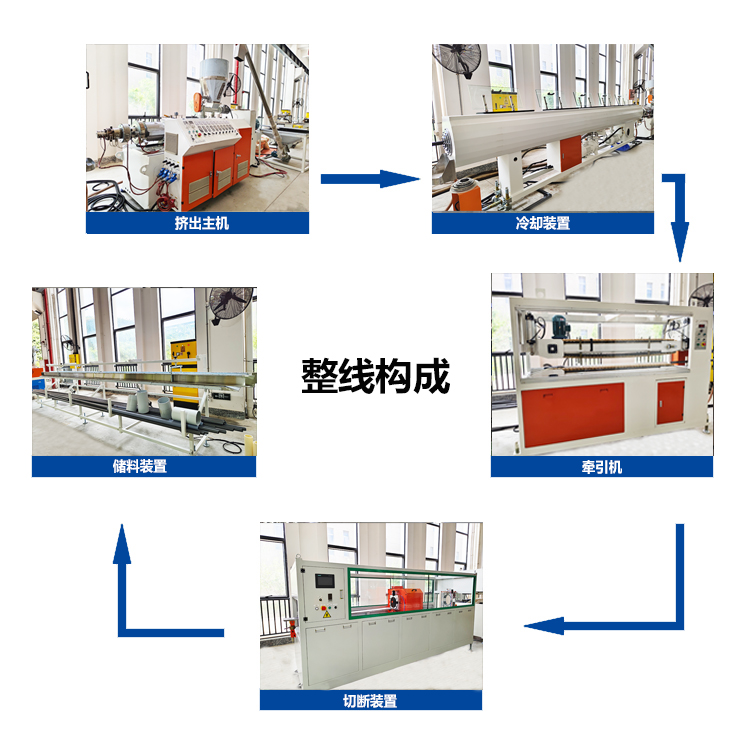

Components of the PVC Pipe Making Machine

1. Conical Twin Screw Extruder

2. PVC Pipe Mould

3. Spraying and Cooling Tanks

4. Haul-Off Machine

5. Cutting Machine

6. Pipe Belling Machine

Advantages of the Machine

High Efficiency: Advanced design ensures high-speed production with uniform plasticization.

Versatility: Capable of producing pipes in a wide range of diameters (16mm to 630mm).

Quality Assurance: Stable temperature control, rapid cooling, and precise calibration ensure high-quality pipes.

Automation: PLC control system synchronizes all components for smooth operation.

Durability: Components like the haul-off machine and cutting machine are designed for long-term use with minimal maintenance.

Summary

This PVC pipe making machine is a comprehensive solution for manufacturers looking to produce high-quality PVC pipes for various applications. Its advanced design, efficient components, and automation capabilities make it a reliable choice for high-capacity production while ensuring consistent quality and durability of the pipes.

.

Every piece of plastic pipe extrusion equipment manufactured by Yaoan undergoes a rigorous pre-sales communication process to fully understand the specific needs of our customers. Our professional technical team then conducts research and design, ensuring strict control over every production process and procedure. After thorough debugging and testing by relevant departments, the PVC pipe machine is delivered to customers with high-standard quality, upholding the manufacturing standards of Yaoan.

PACKAGING:plastic film + stretch film + wooden case + drying agent.

SHIPPING:We place and fix the plastic pipe extrusion equipments well into container and check carefully before closing the container so as to ensure everything is ok for the shipment. (Use steel wire to fix machine and drying agent).

Vacuum calibration device: vacuum sprayingwater chamber for pipe, spraying water tank forpipe,main body is made of stainless steel.Haul off unit: 2 claw, 4 claw,6 claw, 8claw haul offunit for pipe, to adapt manufacturingrequirements for different pipes.Cutting unit: chip-free rotary knife cutting, sawcutting, and planet saw cutting.( with chamferedblade)Diameter enlarger for rigid PVC pipeStacking unit: automatic overturning stacking.Many options for electric control system(suchas:PLC automatic controlsystem), lt has good features of high speed, stable running, and easyoperation.

Technical parameter:

Model | Screw dia(Mm) | Screw speedMax.(rpm) | Power of mainmotor(kw) | Output(kg/h) |

SJZ35/75 | Φ 35/75 | 47.4 | 11 | 35~60 |

SJZ45/97 | Φ 45/97 | 41 | 18.5 | 70~125 |

SJZ50/105 | Φ 50/105 | 38.7 | 22 | 90~140 |

SJZ55/110 | Φ 55/110 | 37.5 | 30 | 120~180 |

SJZ65/132 | Φ 65/132 | 39.1 | 37 | 180~320 |

SJZ80/156 | Φ 80/156 | 37.7 | 55 | 250~450 |

SJZ92/188 | Φ 92/188 | 40 | 110 | 600~800 |