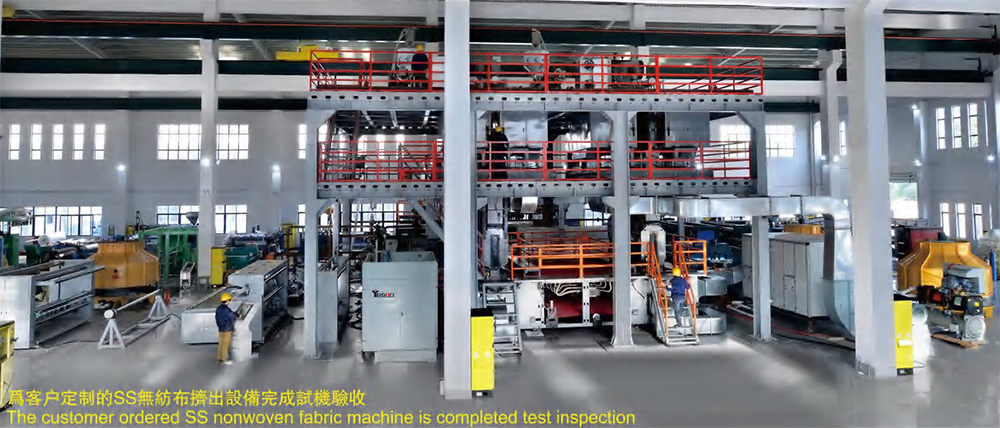

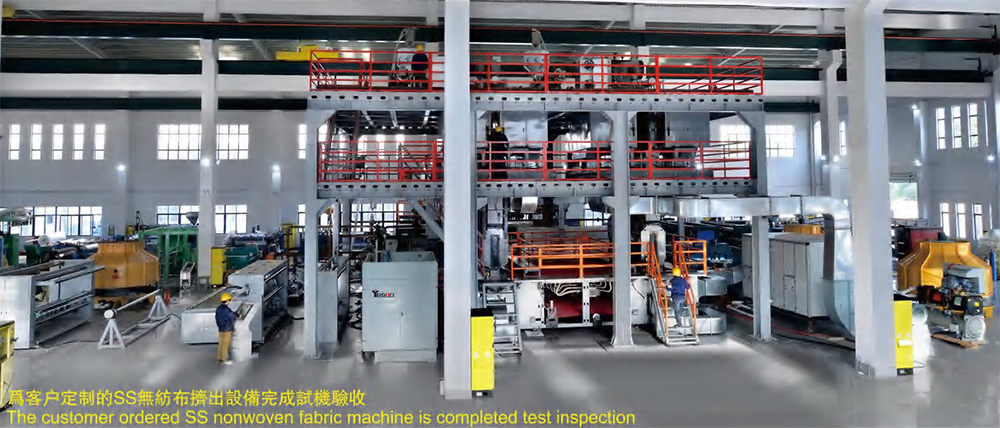

YAOAN'S Double beams PP spunbond nonwoven fabric production line is one type of PP spunbond non woven fabric machine.

The raw material is PPgranule. The machine consists of automatic feedingsystem, melt extrusion spinning system (including single screwextruder,melt pump,filters,spinning chamber,spinneretboard, melt pipe etc),cold stretching system(including sideblowing unit, stretching unit, air channels, and vacuum suctionblowers),web forming machine, calender(thermal bondingmachine),slitting and winding machine, air conditioning andrefrigeration system,automatic controlsystem and othercomponents.

Our Double beams SS spunbond nonwoven fabric production line adopts foreign advanced technology and experience, easyoperation, fully automation, PLC touch screen control, goodquality final product, high speed and high output. Equipment isgenerally 1.6 m wide, 2.4 m wide, or 3.2 m wide, can also becustomized according to customer specific requirements.

Application fields:Medical and health: Operation suit, anti-exposure suit, cap,respirator, massage cloth, adhesive tape etc.

Agricultural :Cover for plant to anti-frost ,insect-frost, insect-resistant sunshades ,awning clothes, packing bags for crops etc.

Industry: Interior decoration for car, train and ship ; back fabricfor man-made carpets etc.

Packing and lining:Bags for business suit, shopping bagspresent bags, dust cover, sleeping bag for children, wardrobeshoes lining, sofa lining, car and household decoration, watershield,filtering material, fabric for roadbed and dam etc.

Our Services:

To keep up with the development of industry related technologies, continuously improve the productivity, automatic grade of operation and minimize energy consumption of of existing machines.

Maintain an open attitude towards customer requirements and work together with them to develop machines.

The double beams SS spunbond nonwoven fabric production lines cannot be allowed for shipment untill the customers confirm the result of machine test with raw material. Our staff also tests machines for several hours to check whether the sizes of plastic products are according to drawings, whether the ampere of motors are stable or not, whether machine runing is steady quietly., whether the machine output is up to manufacturing orders.