YAOAN'S SMS nonwoven fabric production line adopts multi-layer composite technology.

SMS fabric production line is a integration of SS non woven fabric machine and a melt blown fabric machine.

In same logic, YAOAN also OWN SSMS, SSMMS technology. The max. line speed of SSMMS can be 600ms/minute.

YAOAN's spunbond nonwoven extrusion equipment includes single S (PP nonwoven fabric production equipment), double S (SS spunbond equipment), and triple S (SSS spunbond equipment) Spunbond spinning and melting production equipment, integrating spunbond and meltblown technologies, including SMS, SMMS, SSMMS composite production equipment.

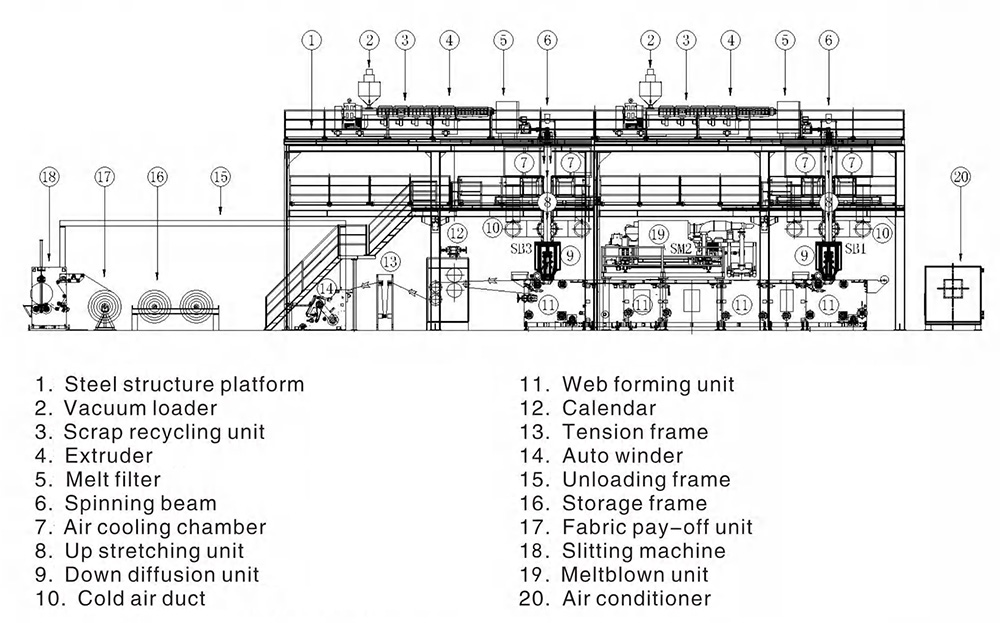

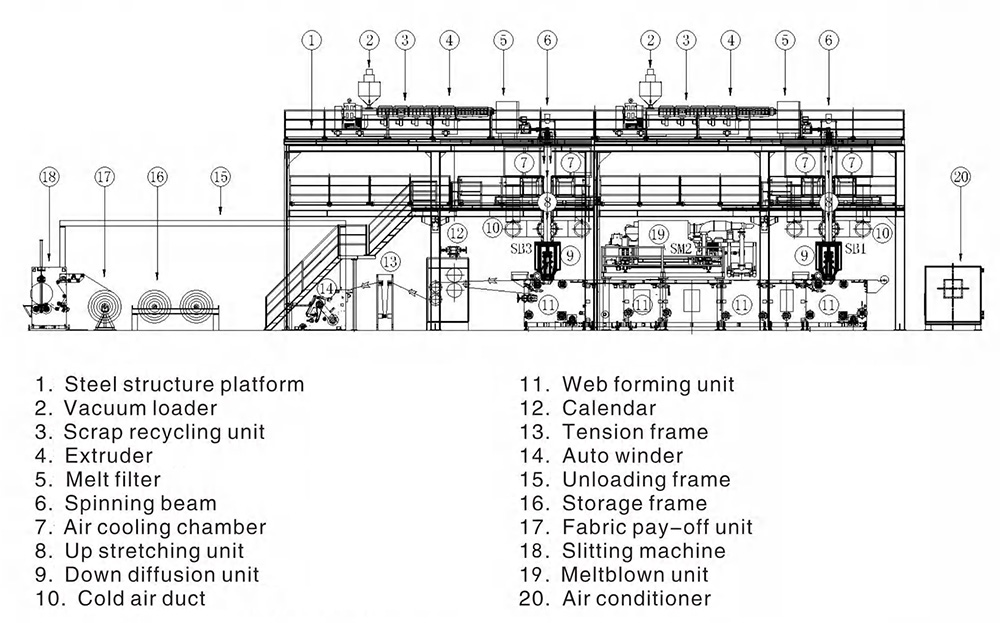

The SMS non woven fabric production line is application for PP chips as raw materials input, undergoes the process of extrusion, spinning, quenching, closure air stretching, web formation, calendaring, winding and cutting as per requirements and then packed for storage and delivery.

Credit Check,ISO, CE, RoSH and Supplier Capability Assessment. company has strictly quality control system and professional test lab.

we have strict quality control regulations on the inspection of spare parts. It is guaranteed by qualified staff and advanced accurate process tooling machines: 6 AXIS CNC machines, laser cutting machines, wire spare engineering machines

The SSMS fabric extrusion lines cannot be allowed for shipment untill the customers confirm the result of machine test with raw material. Our staff also tests machines for several hours to check whether the sizes of plastic products are according to drawings, whether the ampere of motors are stable or not, whether machine runing is steady quietly., whether the machine output is up to manufacturing orders.