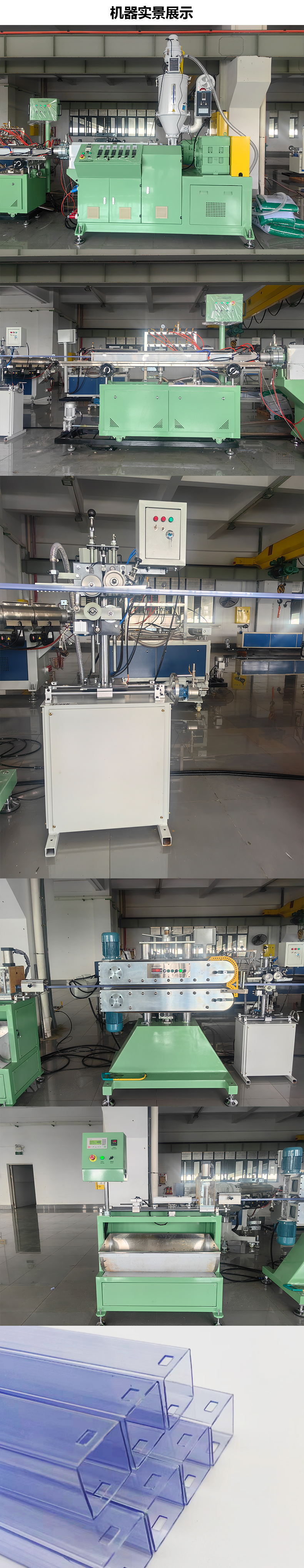

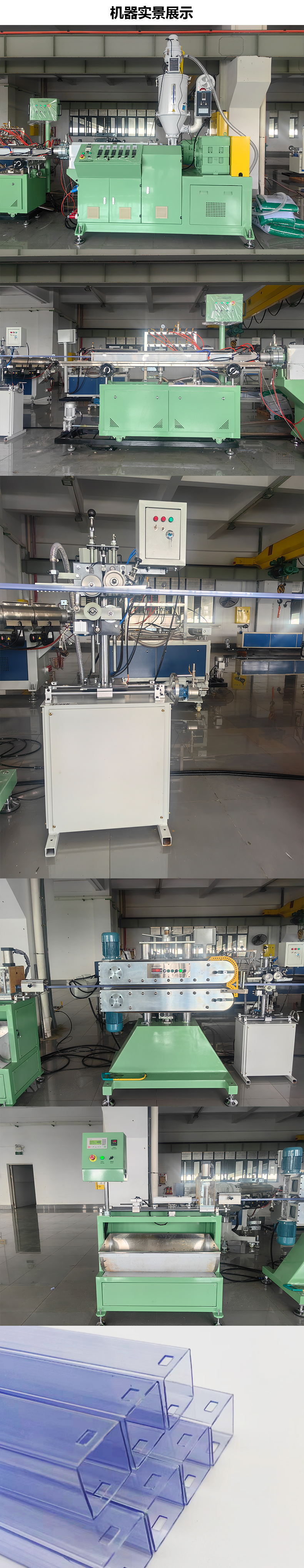

YAOAN'S IC pipe extrusion line is one type of single screw extruder profile extrusion machine. Prominent IC pipe in the market is of PVC. PETG IC pipe is new trendency. YAOAN has two machines for both. The raw material is Clear PVC granule or PETG granule. PVC IC pipe extruder consists of one unit of extruder: suitable PVC clear granule; there is no burnt grains during a long operation; die head and calaibration mold: Special tool steel, long life. vacuum calibration water tank, vacuum grade is freely adjustable; work position can be 3 d ajustable freely and easily; stable working without vibration. haul-off unit, steable pulling, automatic cutter, equiped laser sensor to ensure the length accurate (more or less 0.5mm). It also can integrate a machine combination of hole punching and embody TPR nails. The PETG IC pipe machine is as same as the PVC IC pipe machine except PETG IC pipe madchine needs a dehumidifer for PETG and extruder suitable for PETG. Why choose YAOAN MACHINE: Long time experience, big company, strong R&D human resource.

The YAOAN IC Pipe Extruder is a specialized single-screw extruder profile extrusion machine designed for producing IC pipes (Integrated Circuit pipes) used in the electronics and semiconductor industries. These pipes are primarily made from PVC (Polyvinyl Chloride) or PETG (Polyethylene Terephthalate Glycol), with PETG being a newer trend due to its superior properties. Below is a detailed explanation of the machine's features, configurations, and advantages for both PVC IC pipe and PETG IC pipe production:

PVC IC PIPE Extrusion Equipment

Machine Configuration

Extruder:

Designed for processing clear PVC granules.

Ensures smooth operation without burnt grains, even during prolonged use.

Die Head and Calibration Mold:

Vacuum Calibration Water Tank:

Vacuum grade is freely adjustable for optimal pipe dimensions and surface finish.

Work position is 3D adjustable, allowing for easy and precise alignment.

Stable operation without vibration.

Haul-Off Unit:

Automatic Cutter:

Optional Accessories:

PETG IC Pipe Extrusion Equipment

Machine Configuration

Extruder:

Specifically designed for processing PETG granules.

Includes a dehumidifier to dry PETG granules before extrusion, ensuring optimal material properties.

Die Head and Calibration Mold:

Vacuum Calibration Water Tank:

Haul-Off Unit:

Automatic Cutter:

Optional Accessories:

Key Features of IC Pipe Extruder

High Precision:

Durability:

Versatility:

Efficiency:

Smooth extrusion process with no burnt grains, even during prolonged operation.

Automated cutting and optional accessories reduce manual intervention.

Applications Of IC Pipe Extruder

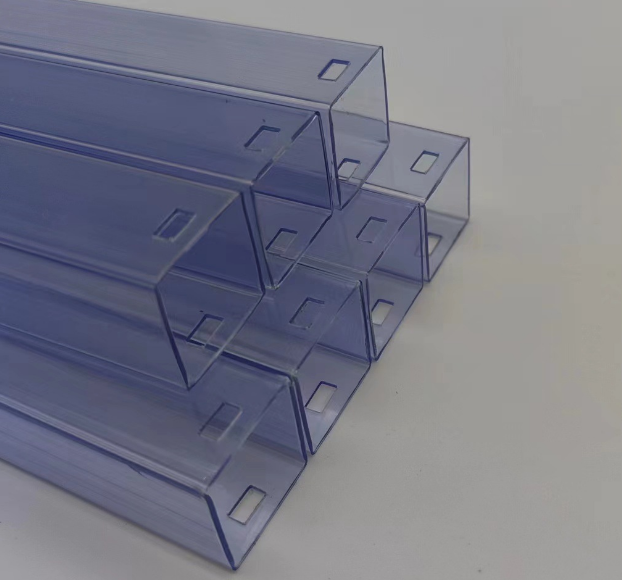

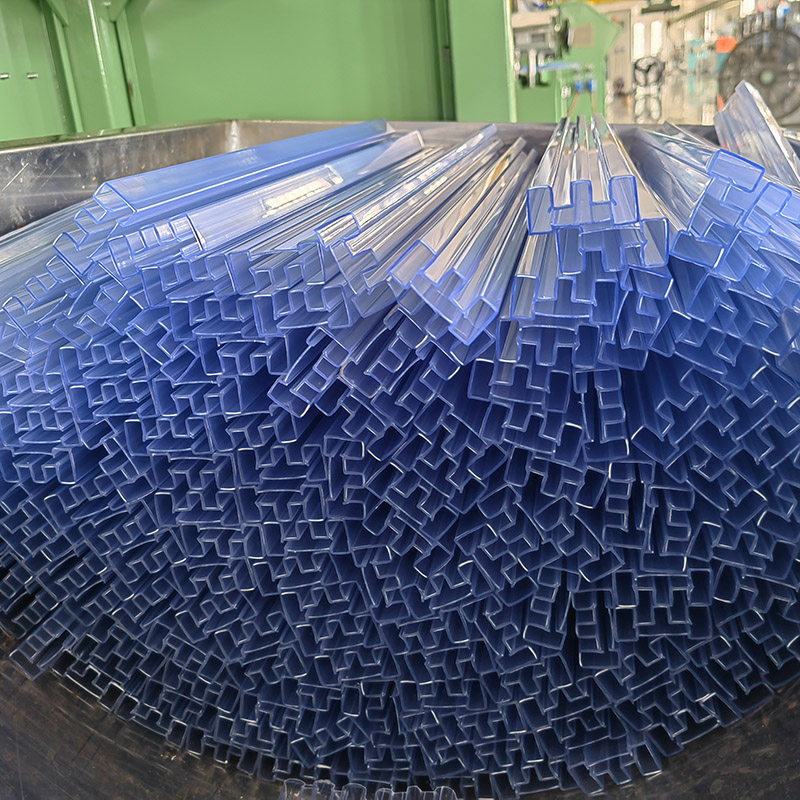

PVC IC Pipes:

Widely used in the electronics and semiconductor industries for protecting and organizing integrated circuits.

PETG IC Pipes:

Gaining popularity due to PETG's superior properties, such as higher clarity, chemical resistance, and durability.

Why Choose YAOAN's IC Pipe Extruder?

Long-Time Experience:

Big Company with Strong R&D:

Global Reputation:

Customization and Flexibility:

Proven Technology:

Conclusion

The YAOAN IC pipe extrusion line is a state-of-the-art solution for producing high-quality PVC and PETG IC pipes. With its precision engineering, durability, and advanced features, it is the ideal choice for manufacturers in the electronics and semiconductor industries. YAOAN's long-time experience, strong R&D capabilities, and global reputation make it a trusted partner for businesses seeking reliable and efficient extrusion machines. Whether for traditional PVC IC pipes or the emerging trend of PETG IC pipes, YAOAN delivers unmatched performance and quality.