YAOAN's POE medical breath hose extrusion machine is a high-precision, versatile medical tube production system designed for manufacturing spiral breath pipes used in medical and industrial applications. The system integrates advanced technology and user-friendly features to ensure efficiency, precision, and flexibility.

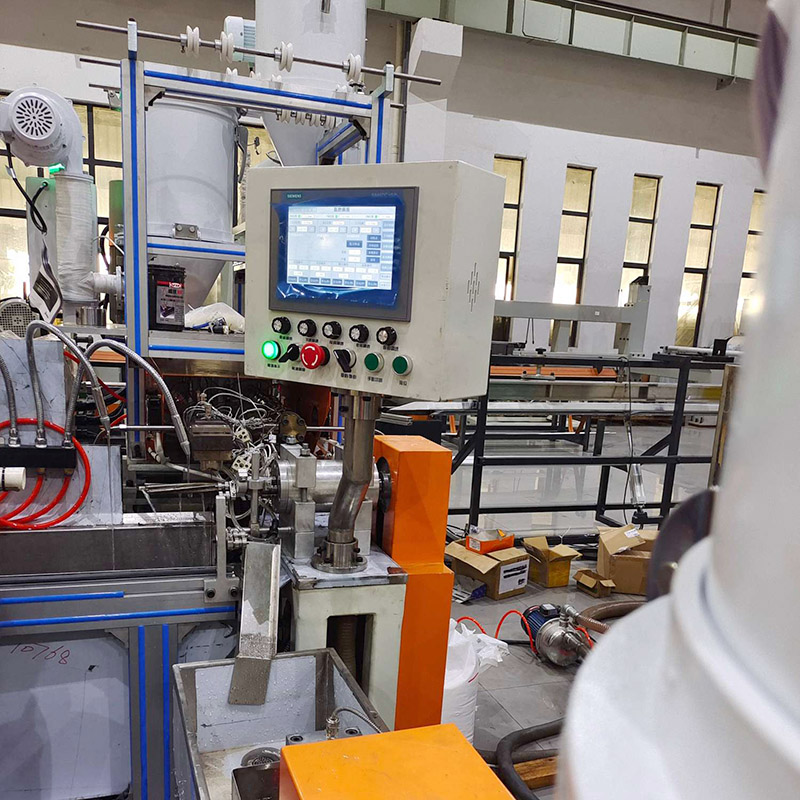

Dual Extruders with 3-Directional Movement Bases:

The extruders are mounted on 3-directional movement bases driven by servo motors, allowing precise alignment and positioning of the die heads.

This human-friendly design simplifies die head adjustments, reducing setup time and improving operational efficiency.

Compatible with PP, POE, and PVC materials (with a PVC-specific extruder for PVC spiral breath pipes).

Dual Die Heads:

Enables coextrusion for multi-layer tube structures, combining materials with different properties (e.g., flexibility, chemical resistance, or biocompatibility).

Ensures uniform material distribution and precise layer thickness.

Spiral Forming Machine:

Shapes the extruded tube into a spiral structure, enhancing flexibility and preventing kinking or folding during use.

The spiral design ensures continuous airflow in medical applications, such as respiratory tubes, and improves durability.

Water Cooling Tanks:

The first tank rapidly cools the tube to solidify its shape.

The second tank ensures complete cooling before cutting.

Two-stage cooling system:

Maintains dimensional stability and precise tolerances.

Automatic Cutter:

Equipped with a servo-driven cutting mechanism for precise length control (±0.1mm accuracy).

Ensures clean, burr-free cuts for high-quality finished products.

Stack Table:

Automatically collects and organizes finished tubes for packaging, reducing manual handling and improving workflow efficiency.