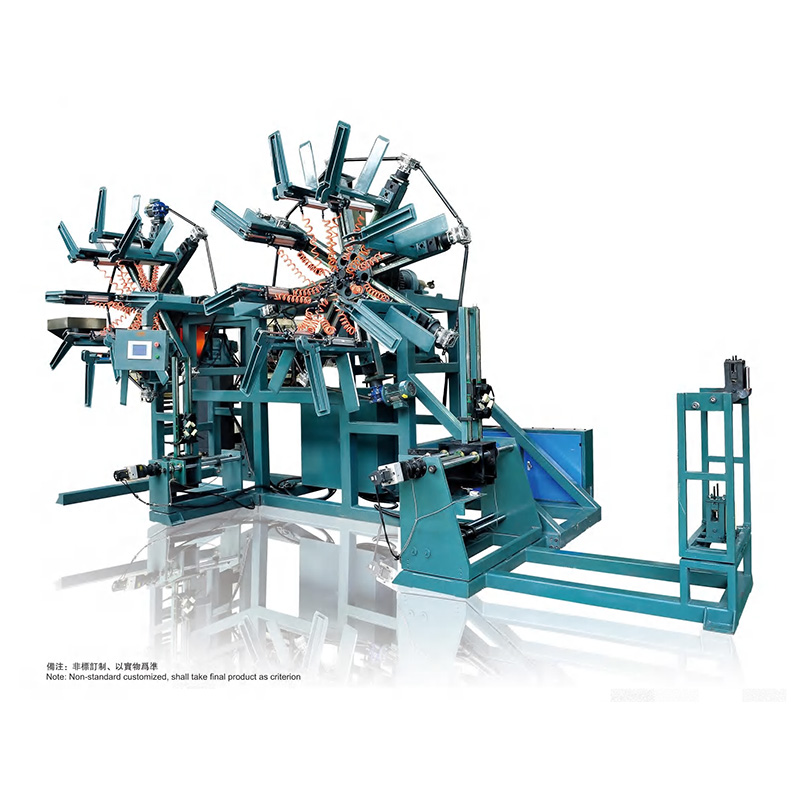

The winding tension is adjusted by the inverter that has atension control module; Product is aligned well by aservo motor.

Two station winder main technical parameters:

Suitable pipe diameter:16-90mm

Maximum coil thickness(OD-lD difference):550mm

Maximum coil width:510mm

Maximum winding length/coil: ø20 mm, 1500m

Winding motor power: 2*5.5KW

Align motor power:2*0.75KW

Coil inside diameter:550-1650

R & D Center

Keeping abreast of industry-related technological developments, we continue to improve the productivity and automated operation of existing dual station winding equipments and minimize energy consumption.

Maintain an open attitude towards customer requirements and work together with them to develop machines: A. We can produce machines according to customer drawings and blueprints B. We can work together with customers to develop new machines for their special products.

Afer-sales service

We provide 100% service, including bulk and customized small packaging, as well as various delivery terms such as FOB, CIF, DDU, and DDP. Let us help you find the best solution to all your needs.

We offer attentive pre-sales and after-sales services. We manufacture dual station winding equipments that meet customer satisfaction and provide after-sales support, including installation, extruder startup and operation, and personnel training.