Key Components of a glasses frame CA sheet machine

1. Resin Handling System

Stores and feeds cellulose acetate (CA) resin pellets into the extruder.

Includes a drying system to dehumidify hygroscopic CA resin, ensuring moisture-free processing.

2. Extruder

Core unit for melting and homogenizing CA resin.

Equipped with a single-screw or twin-screw design and precise temperature control zones to optimize material flow.

3. Flat Die

Shapes molten CA into a continuous flat sheet.

Die geometry directly controls final sheet thickness and width uniformity.

4. Calendering/Polishing Rolls

A series of thermally regulated rollers (heated/cooled) to calibrate sheet thickness, surface finish, and flatness.

Gradual cooling prevents warping or surface defects.

5. Cooling System

Solidifies the extruded sheet using air knives, water baths, or chilled rollers, tailored to production specifications.

6. Haul-Off Unit

Maintains controlled tension and line speed via servo-driven mechanisms to ensure consistent thickness and dimensional accuracy.

7. Cutting & Stacking System

Cut-to-length system with precision blades for sheet sizing.

Automated stacking of sheets for packaging or downstream processing.

8. PLC Control System

Centralized Programmable Logic Controller (PLC) monitors and adjusts critical parameters: temperature profiles, line speed, pressure settings, real-time quality feedback.

Introduction to Multi-layer CA Sheet Extrusion Line

Multi-layer sheet extrusion equipment is a specialized production system for manufacturing cellulose acetate sheets. According to the specific requirements of customers, our cellulose acetate sheet production line for eyeglass frames can produce single-layer to six-layer cellulose acetate sheet products with thicknesses ranging from 1 to 6 millimeters. These products are widely used in the eyewear industry for the manufacturing of eyeglass frames, as well as in packaging and decorative laminates.

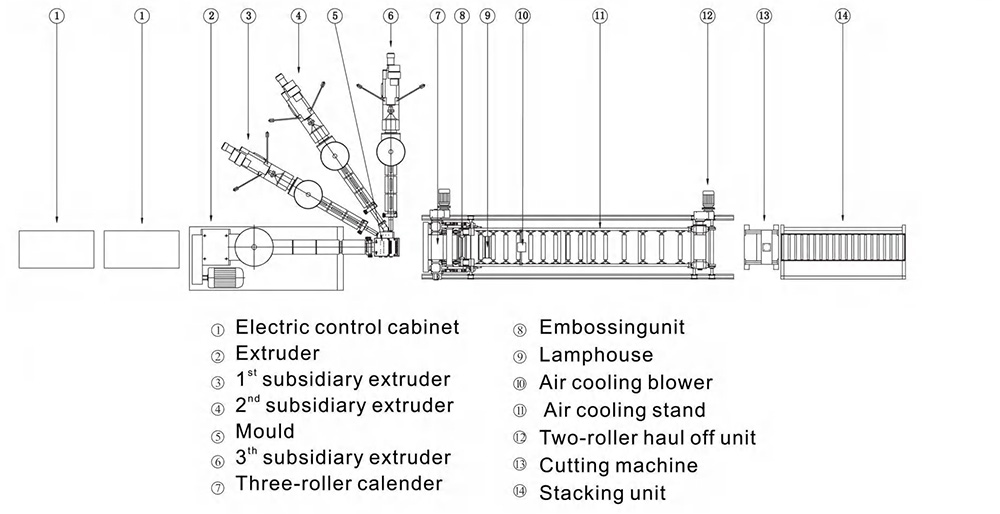

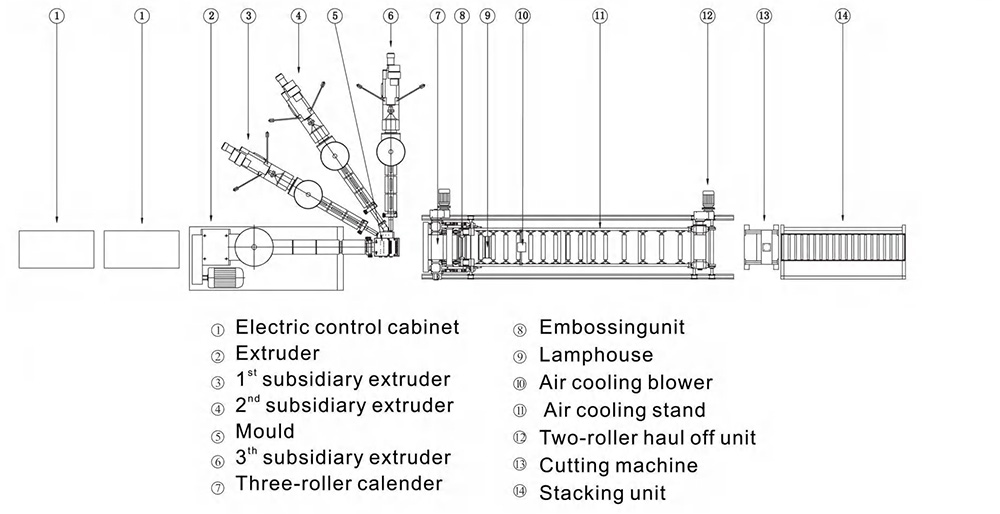

Process Overview of 3 layer CA spectacle frame sheet machine

Material Preparation:

Cellulose acetate resin pellets were dried and dehumidified and fed into the extruder.

Extrusion:

The resin is melted and homogenized in the extruder and then forced through a flat die to form a continuous sheet.

Calendering and cooling:

The sheet is passed through calendering rollers to achieve the desired thickness and surface finish.

A cooling system cures the sheet while maintaining its dimensional stability.

Cutting and Stacking:

The cooled sheets are cut to size and stacked for packaging or further processing.

Our Payment & Shipping Terms

Minimum Order Quantity: 1

Packaging Details: WOODEN BOX, sea worthy

Delivery Time: 30-90 DAYS

Payment Terms: TT,LC

Packaging and Shipping

PACKAGING:plastic film + stretch film + wooden case + drying agent.

DELIVERY:About 120 days (all new parts)

SHIPPING:We place and fix the cellulose acetate spectacle frame sheet machines well into container and check carefully before closing the container so as to ensure everything is ok for the shipment. (Use steel wire to fix machine and drying agent).