PS multiple layers sheet extrusion machine used multi-formula weighing automatic batching system.New screw structure, good mixing and plasticization,high output. Whole line is of compact design, low energy consumption.

Introduction to GPPS.HIPS Coextrusion Sheet Machine

1. Overview of GPPS and HIPS Materials

GPPS (General Purpose Polystyrene): A transparent, rigid plastic material commonly used in packaging, disposable containers, and consumer goods due to its clarity and ease of processing.

HIPS (High Impact Polystyrene)**: A modified version of GPPS with added rubber to improve impact resistance, making it suitable for applications like refrigerator liners, automotive parts, and food packaging.

2. Coextrusion Technology

Coextrusion is a manufacturing process that combines multiple layers of materials into a single sheet or film. This technology is widely used in the production of GPPS/HIPS sheets, offering benefits such as enhanced mechanical properties, improved barrier performance, and cost efficiency.

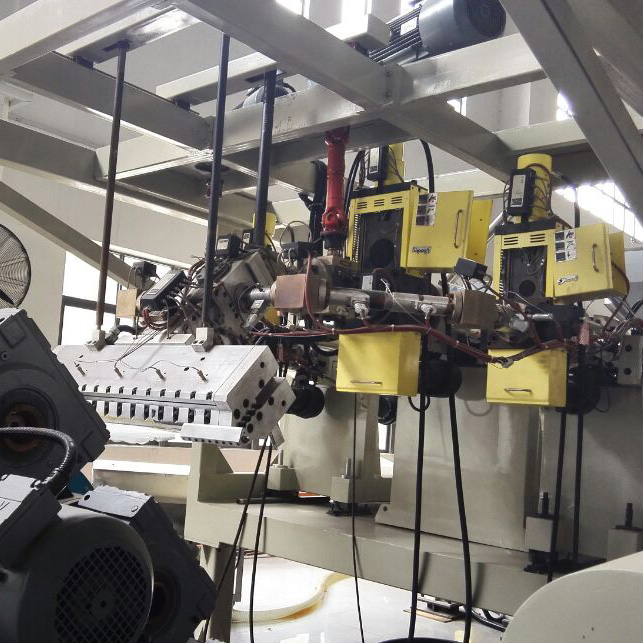

3. Key Components of a GPPS/HIPS Coextrusion Sheet Machine

Extruders: Multiple extruders are used to melt and feed the GPPS and HIPS materials into the coextrusion die.

These PS multi-layer sheet extruders are equipped with precise temperature and pressure controls to ensure consistent material flow.

Coextrusion Die A specialized die designed to layer the molten GPPS and HIPS materials into a uniform sheet.

The die configuration determines the thickness and structure of the final product.

Cooling and Calendering System: After extrusion, the sheet passes through cooling rollers and calendering units to achieve the desired thickness, surface finish, and dimensional stability.

Cutting and Stacking Unit: The finished sheet is cut to size and stacked for packaging or further processing.

4. Applications of GPPS/HIPS Co-extrusion PS sheet extrusion line

Packaging: Used in blister packs, food trays, and disposable containers due to their durability and clarity.

Appliances: Commonly used in refrigerator liners, door panels, and interior components due to their impact

resistance and thermal insulation properties.

Automotive: Employed in interior trim and dashboard components for their lightweight and aesthetic appeal.

5. Advantages of HIPS GPPS refrigerator liner sheet production line

High Efficiency: Modern machines are designed for rapid production, with some models offering speeds three times faster than traditional equipment.

Versatility: Capable of producing sheets with varying thicknesses, colors, and surface finishes to meet diverse industry needs.

Energy Efficiency: Advanced cooling systems and low-energy consumption designs reduce operational costs.

6. Industry Trends and Innovations

- **Automation**: Increasing integration of automated controls and monitoring systems to enhance precision and

reduce downtime.

- **Sustainability**: Development of eco-friendly production lines that utilize recycled materials and minimize waste.

- **Customization**: Growing demand for tailored solutions, such as multi-layer coextrusion for specialized applications.

7. Conclusion

HIPS GPPS refrigerator liner sheet production lines are essential for producing high-quality plastic sheets used in various industries.

With advancements in technology and a focus on sustainability, these machines continue to evolve, offering greater efficiency, versatility, and environmental benefits.