YAOAN TPU TPR RUBBER BAND EXTRUSION LINE

Introduction

Plastic rubber bands extrusion line also called TPR rubber band extruder, TPU rubber band extruder, TPE rubber band extruder.

The raw material is plastic pellets: TPR, TPU, TPE

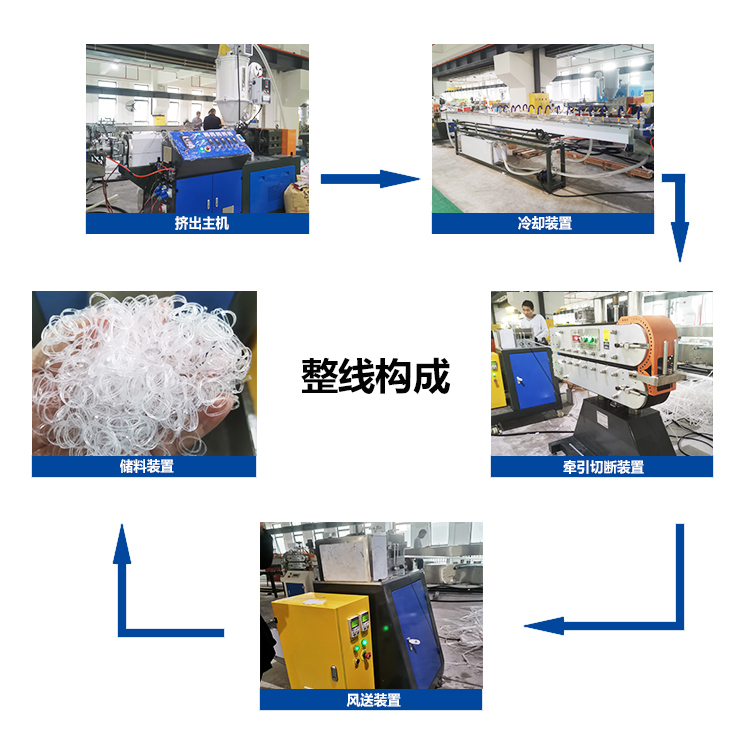

The process step: extruder (plastic melt)- pipe die head (plastic pipe extrusion)- water cooling--haul-off-cut into rings.

Machine type: single color style rubber band, 2 color rubber band, 3 color rubber band

band size: DIA.10-DIA200MM

Upon self production demand, customer may chooseour single-color, or multi-colortypemain extruder structure, combined with extrusion die, water coolingtank, haul-off machine, cutting machine,windtransportation system, etc. The products are widely used in toy, decoration and gift packaging etc.

Brief introduction of plastic rubber band extrusion machine

The plastic TPU rubber bands extrusion line is a specialized manufacturing system designed to produce rubber bands from thermoplastic materials such as TPR (Thermoplastic Rubber), TPU (Thermoplastic Polyurethane), and TPE (Thermoplastic Elastomer). These materials are supplied in pellet form and processed through a series of steps to create rubber bands of various sizes and colors. Below is a detailed breakdown of the process and machine types:

Process steps of elastics extrusion equipment

Extruder (Plastic Melting):

The raw material (TPR, TPU, or TPE pellets) is fed into the extruder.

The extruder heats and melts the plastic pellets, transforming them into a molten state.

The molten plastic is then pushed through the extruder's screw mechanism.

Pipe Die Head (Plastic Pipe Extrusion):

The molten plastic is forced through a pipe-shaped die head, forming a continuous plastic pipe.

The die head determines the diameter and thickness of the extruded pipe.

Water Cooling:

Haul-Off:

Cutting into Rings:

Plastic Rubber Band Extrusion Machine Types

Single Color Rubber Band Extrusion Line:

2-Color Rubber Band Extrusion Line:

3-Color Rubber Band Extrusion Line:

Band Size

Key Features of the TPR Rubber Bands Extrusion Line

High Efficiency: Automated process ensures consistent output and high production rates.

Customizable: Adjustable die heads and cutting systems allow for customization of band size, thickness, and color.

Material Versatility: Compatible with TPR, TPU, and TPE materials, offering flexibility in product properties (e.g., elasticity, durability, and softness).

Energy-Efficient Cooling: Water cooling systems ensure rapid and uniform cooling of the extruded pipe.

Applications OF Elastics Extrusion Equipment

Stationery: Rubber bands for office or school use.

Packaging: Bundling and securing items.

Industrial: Heavy-duty rubber bands for industrial applications.

Crafts and DIY: Decorative or functional rubber bands for creative projects.

This TPR rubber bands extrusion line is a versatile and efficient solution for producing rubber bands in various sizes, colors, and materials to meet diverse market demands.