YAOAN vertical drain board extrusion line is a highly efficient and integrated production line designed for manufacturing prefabricated vertical drain (PVD) boards. These boards are widely used in civil engineering and construction projects for soil consolidation, drainage, and stabilization. The drain board machine combines profile extrusion and ultrasonic welding technologies to produce high-quality drain boards with precision and speed. Below is a detailed overview of the machine's features, configurations, and production process:

PP Drain Board Extrusion Machine Overview:

Purpose: Production of prefabricated vertical drain boards.

Raw Materials:

PP Pellets: Used for extruding the core strap.

PET Non-Woven Fabric: Used for wrapping and welding the core strap.

Line Speed: 20-35 meters/minute.

Key Features: High-speed production, precise welding, and consistent quality.

Production Process:

PP Strap Extrusion:

The PP pellets are melted and extruded through a die head to form the core strap of the drain board.

Cooling:

The extruded PP strap is cooled in a water tank to solidify its shape.

Non-Woven Fabric Wrapping:

The cooled PP strap is wrapped with PET non-woven fabric using a pay-off stand and wrapping table.

Ultrasonic Welding:

The overlapping edges of the PET non-woven fabric are welded together using ultrasonic welding technology, ensuring a strong and durable bond.

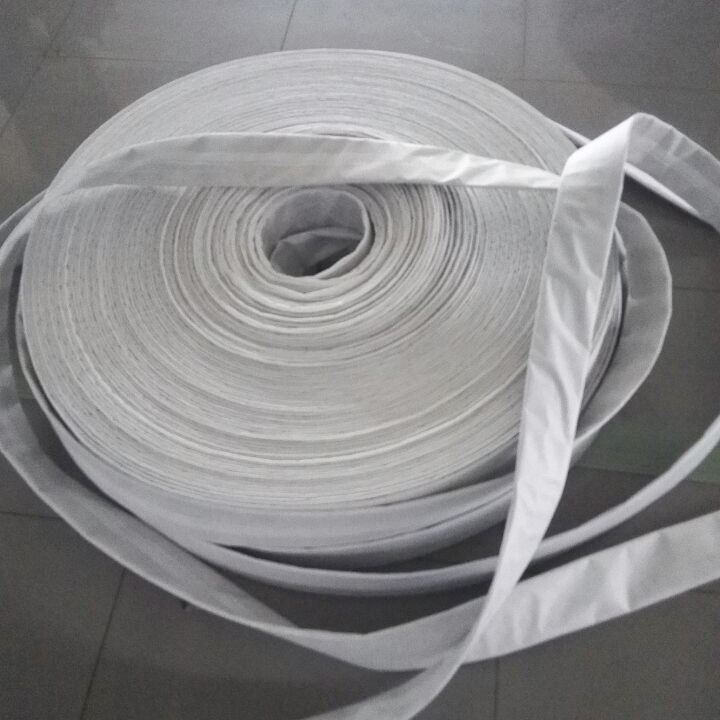

Haul-Off and Winding:

The finished drain board is pulled through the line by a haul-off unit and wound onto rolls using a two-station winder.

Drain Board Machine Configurations:

Extruder:

Melts and extrudes PP pellets to form the core strap.

Die Head:

Shapes the molten PP into the desired profile for the core strap.

Water Tank:

Cools the extruded PP strap to solidify its shape.

Haul-Off Unit:

Pulls the strap through the production line at a controlled speed.

PET Non-Woven Fabric Pay-Off Stand:

Holds and feeds the PET non-woven fabric for wrapping the PP strap.

PET Non-Woven Fabric Wrapping and Ultrasonic Welding Table:

Wraps the PP strap with PET non-woven fabric and welds the overlapping edges using ultrasonic technology.

Two-Station Winder:

Winds the finished drain board onto rolls for storage or transportation.

Advantages of Prefabricated Vertical Drain Boards:

High Drainage Capacity: Efficiently removes water from soil, accelerating consolidation.

Durability: Resistant to chemical and environmental degradation.

Lightweight: Easy to handle and install.

Cost-Effective: Reduces construction time and costs by improving soil stability.

Customizable: Available in various sizes and specifications to meet project requirements.

Drain Board Machine Applications:

Civil Engineering Projects:

Used for soil consolidation and stabilization in road construction, embankments, and foundations.

Land Reclamation:

Accelerates drainage and consolidation in land reclamation projects.

Airport and Port Construction:

Provides soil stabilization and drainage in large-scale infrastructure projects.

Environmental Engineering:

Used in landfill sites and wastewater treatment facilities for drainage and filtration.

Conclusion:

The YAOAN Vertical Drain Board Making Machine is a state-of-the-art solution for producing high-quality prefabricated vertical drain boards. Its integrated design, combining profile extrusion and ultrasonic welding technologies, ensures efficient and precise production. The vertical drain board extrusion line's ability to handle PP and PET non-woven fabric results in durable, high-performance drain boards suitable for a wide range of civil engineering and construction applications. Whether for soil consolidation, land reclamation, or infrastructure projects, this drain board machine delivers reliable performance and consistent quality.