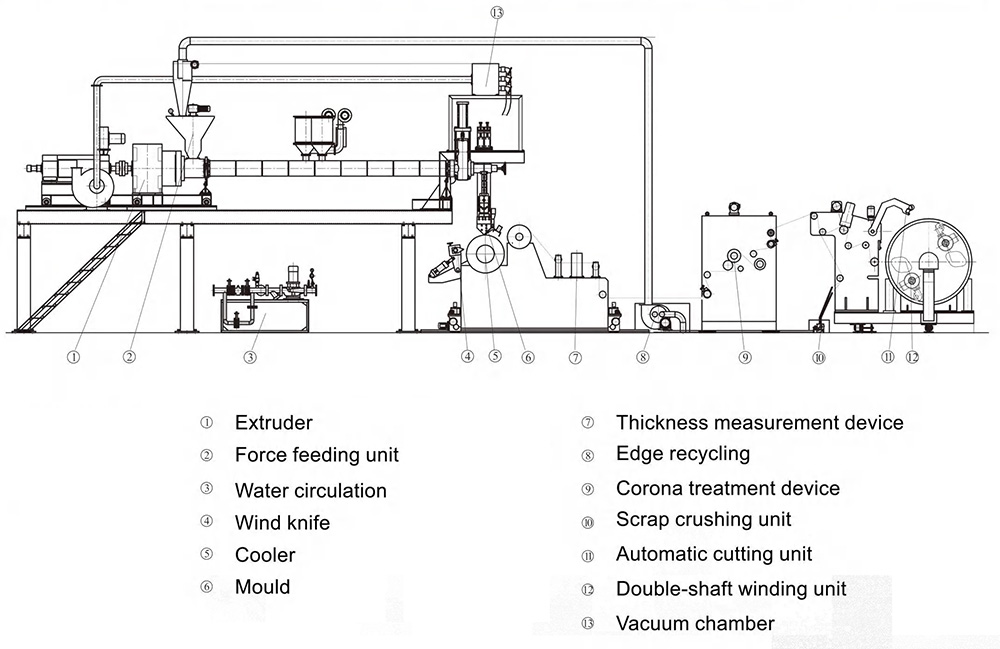

CPE Cast Film Machine's Process

In the cast film extrusion process, molten polymer is extruded through a slit die onto a chilled, highly polished rotating roller where it undergoes quenching (rapid cooling) from one side. The rotational speed of this roller governs the draw ratio and ultimately determines the final film thickness. The film is subsequently transferred to a second roller for cooling on the opposite side. Following this staged cooling, the film passes through a series of rollers in the take-off system before being wound onto a roll.

A similar methodology can be employed to produce thicker polymer sheets. The distinction between sheets and films lies solely in their thickness specifications: by industrial definition, sheets exhibit a thickness exceeding 0.25 mm, whereas materials below this threshold are classified as films.

The cast film process is utilized for films with extremely tight tolerances or for low-viscosity resins. Most flat dies employ a T-slot or coat-hanger design, which includes a flow distributor to disperse the flowing polymer across the entire width of the die. This is followed by alternating narrow slots and open channels downstream to achieve the desired flow distribution and pressure drop. The majority of CPE cast film machine production lines currently in operation are co-extrusion lines. These combine the extruded layers from up to seven extruders into a single product, either through a multi-manifold die or a single-manifold die equipped with a feed block.