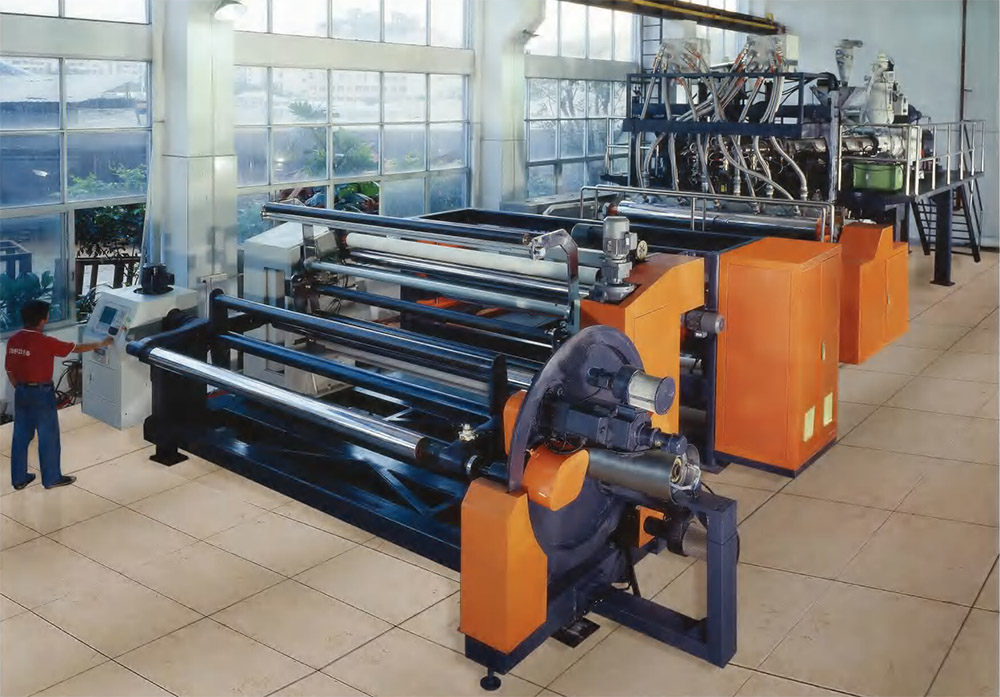

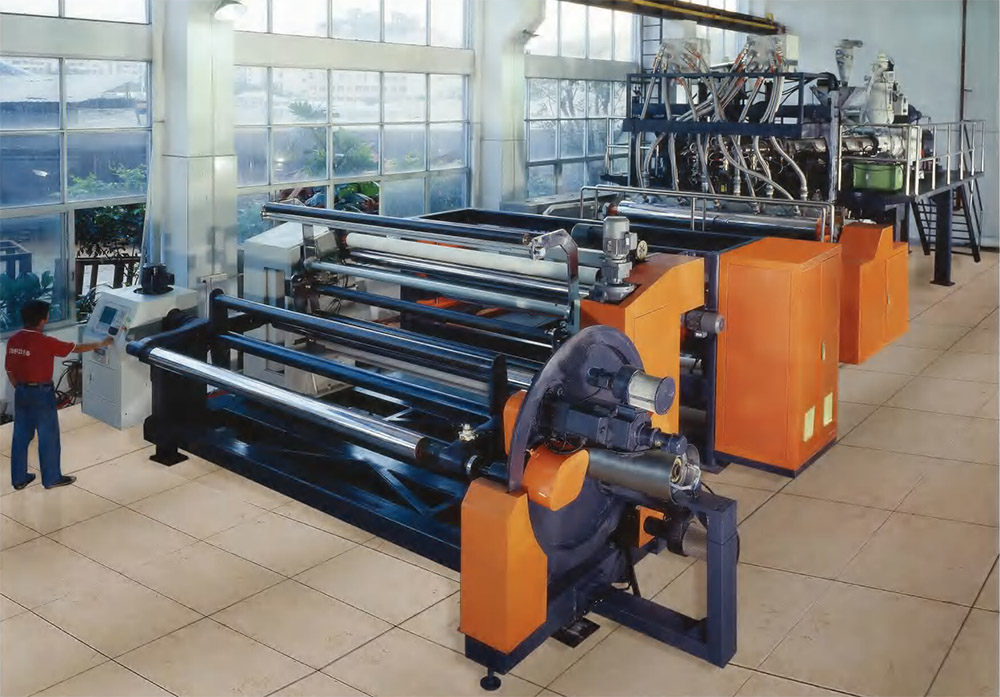

Introduction of Three-layer Cast Film Co-extrusion Machine

Advanced structure of whole line assures stableand high-speed extrusion of cast film.

Professional design of screw guarantee sufficient plasticization and stable extrusion of material.

Effective width ofdie can be made up to 5000mm,

adjust die-lipmanually/automaticaly,multi-channel,and multilayer co-extrusion, which fit for the co-extrusion of many kinds material.

Precise and reasonable design of calendar,which guarantee precise surface Temp.of roller.

We can provide many types of three-layer cast film co-extrusion machine according to different requirements of the customer's material.

Adopts special main extruder,can be applicable for the manufacturing:PP/PE cast film(CPP)/(CPE)EVOH/PA package and obstruct film , Sanitary film. Embossing and patterned film,stretch film,adhesive film,protection film.

3-Layer Cast Film Machine Overview:

Key Components:

Extruder: Equipped with a specially designed screw for efficient mixing and high plasticizing.

Hydraulic Screen Changer: Ensures continuous production by filtering impurities without stopping the line.

Static Mixer: Eliminates temperature gradients, improves mixing, and enhances plasticizing.

T-Die: Top automatic casting die with thickness gauge and APC (Automatic Profile Control) for real-time thickness adjustment.

Chill Roll Unit:

Trim Unit: Trims the edges of the film for uniformity.

Recycling System: Online recycling of edge trimmings to reduce waste and production costs.

Haul-Off Unit: Pulls the film through the production line at a controlled speed.

Automatic Winder:

Model Specifications:

| Model Number | CX-CFL-CPP/CPE2000 | CX-CFL-CPP/CPE2800 |

|---|

| Applicable Raw Materials | LDPE, LLDPE, HDPE, EVA, PP | LDPE, LLDPE, HDPE, EVA, PP |

| Product Width | 1650mm | 2500mm |

| Product Thickness | 0.02mm - 0.12mm | 0.02mm - 0.12mm |

| Maximum Extrusion Volume | 300kg/h - 400kg/h | 500kg/h - 700kg/h |

| Number of Film Layers | 3 | 3 |

| Screw Diameter | 75mm*2, 90mm | 90mm*2, 120mm |

| Overall Dimensions | 18m4m4.5m | 22m6m5.5m |

PEVA Raincoat Cloth Film Machine Specifications:

Product Description:

Main Parameters:

Web Width: ≤ 2100mm

Film Thickness: 0.01mm - 0.5mm

Material: LDPE, LLDPE, HDPE, MDPE

Rolling Diameter: ≤ φ500mm (max)

Capacity: 180-250kg/h

Running Speed: 30m - 80m/min

Machine Size: 2200030002900mm

Machine Configurations:

Extruder Part:

Die Head Unit:

Chilling roll unit (cast film forming Unit):

Cooling stand:

winding Unit:

Electric Control Unit:

Design and Configuration Customization:

Custom Design: We offer tailored designs based on customers' specific requirements for finished products. Customers are encouraged to provide samples of their desired products for reference.

Suggestions Welcome: We welcome any reasonable and profitable suggestions or indications to optimize the production line.

Quality Assurance and After-Sales Service:

One-Year Warranty: Covers any manufacturing defects.

Lifetime Service: Ongoing support and maintenance to ensure long-term performance.

Production Base: Our facility produces 5,000 tons of film products annually. Customers are welcome to visit for sampling, proofing, and business negotiations.

Additional Notes:

Pictures for Reference: The device images provided are for reference only. We encourage customers to visit our plant for a firsthand look.

Final Pricing: Depends on specific needs and configurations. We offer a variety of options to suit different budgets and production goals.

Why Choose YAOAN?

Innovative Technology: Patented designs and advanced features ensure high-quality output.

Customizable Solutions: Tailored to meet specific production requirements.

Cost-Effective: Edge material recycling and efficient energy use reduce operational costs.

Reliable Support: Comprehensive after-sales service and technical support.

For more information or to discuss your specific needs, feel free to contact us. We look forward to collaborating with you to achieve your production goals!

Afer-sales service

We provide 100% service. Bulk and customized small packaging, FOB, CIF, DDU and DDP. Let us help you find the best solution for all your concerns.

We practise the service principle that 'customer is God'. We provide thoughtful pre-sales and after-sales service. We produce cast film extrusion machine that satisfy our customers and provide after-sales service including installation, startup operating extrusion machines, and personnel training. Customer compliments are our greatest wish.