CPP Cast Film Extrusion Line is a highly advanced and versatile system designed for the production of high-quality cast films. It is characterized by its high-speed stability, specialized screw design, and automated operation, making it suitable for a wide range of applications, including CPP (Cast Polypropylene), CPE (Cast Polyethylene), high-barrier films, unidirectional stretched films, and more. Below is a detailed overview of the machine's features, specifications, applications, and process.

Key Features:

High-Speed Stability: Ensures consistent production at high speeds.

Specialized Screw Design: Guarantees stable extrusion after material plasticization.

Automation: Fully automated operation for efficiency and precision.

Versatility: Suitable for single-layer and multi-layer co-extrusion.

Wide Material Compatibility: Processes PE, PP, PA, PET, EVA, and more.

High-Quality Output: Produces films with tight tolerances and excellent surface finish.

Basic Information:

| Parameter | Details |

|---|

| Model Number | AF-65&120&65 |

| Product Type | Extrusion Molding Machine |

| Feeding Mode | One Feed |

| Assembly Structure | Integral Type Extruder |

| Screw Type | Single-Screw |

| Engagement System | Intermeshing |

| Screw Channel Structure | Non-Deep Screw |

| Exhaust | No Exhaust |

| Automation | Fully Automatic |

| Computerized | Yes |

| Transport Package | Sea-Worthy Packing |

| Specifications | 1400030002500mm |

| Trademark | YAOAN (ANFU) |

| Origin | Dongguan, Guangdong |

| HS Code | 8477209000 |

| Production Capacity | 50 Sets Per Year |

Product Description:

The CPP Cast Film Extrusion Line is designed for high-speed, specialized, and automated production of cast films. It is optimized for various raw materials, including PE, PP, PA, PET, and EVA. The line is suitable for producing:

CPP and CPE Cast Films

High-Barrier Films (e.g., EVOH and PA for food packaging)

Online Unidirectional Stretched Films

LLDPE, LDPE, and EVA Films

Felt Films and Cling Films

3-Layer Co-Extrusion Cast Film Machine:

| Parameter | Details |

|---|

| Structure | A/B/C, A/B, A/B/A |

| Product Width | 1000-4500 mm |

| Product Thickness | 0.012-0.05 mm |

| Maximum Line Speed | 30-180 meters/minute |

| Features | High-speed surface winding device and online slitting device. |

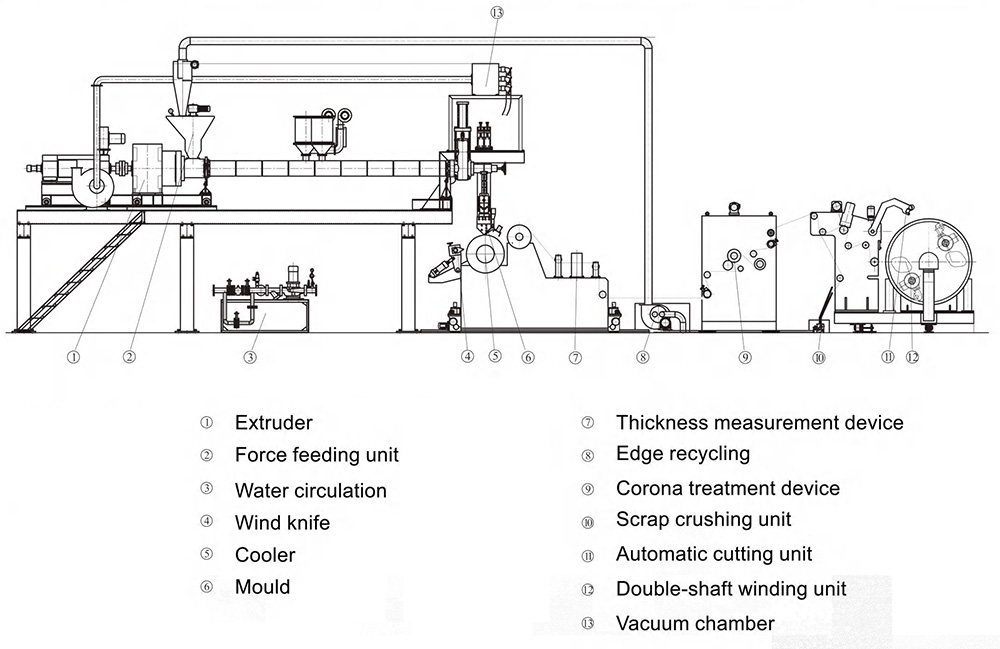

Cast Film Extrusion Process:

Extrusion: The polymer melt is extruded through a T-die.

Quenching: The film is quenched on a chilled, highly polished casting roller.

Drawing: The speed of the roller controls the draw ratio and final film thickness.

Cooling: The film passes to a second roller for cooling on the opposite side.

Winding: The film travels through a series of rollers and is wound onto a roll.

Die Design:

T-Slot or Coat-Hanger Design: Includes a flow distributor to spread the polymer melt across the die width.

Flow Distribution: Alternating narrow slots and downstream open areas ensure even flow and pressure drop.

Co-Extrusion: Most cast film lines use multi-manifold dies or single-manifold dies with feed blocks to combine layers from up to seven extruders.

Applications:

Food Packaging: High-barrier films for extended shelf life.

Industrial Films: CPP, CPE, and other specialty films.

Stretch Films: Unidirectional and cling films for packaging.

Medical Films: High-precision films for medical applications.

Consumer Goods: Films for various consumer products.

Advantages:

High Precision: Produces films with tight tolerances.

Efficiency: High-speed production with minimal downtime.

Versatility: Suitable for a wide range of materials and applications.

Quality: Excellent surface finish and mechanical properties.

Customization: Can be tailored to meet specific production requirements.

Why Choose YAOAN?

Advanced Technology: Combines high-speed extrusion with precision control.

Reliable Performance: Built with high-quality components for durability.

Comprehensive Support: Includes installation, training, and after-sales service.

Global Reach: Proven success in various industries worldwide.

For more information or to discuss your specific requirements, feel free to contact us. We look forward to helping you achieve your film production goals!