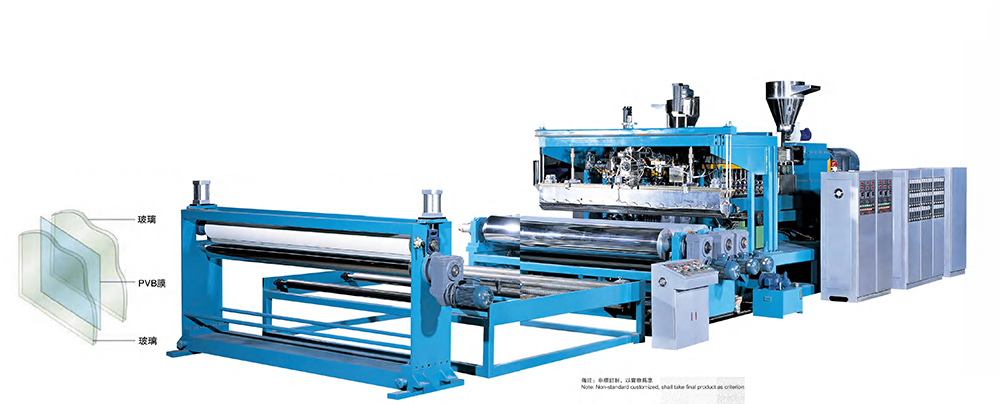

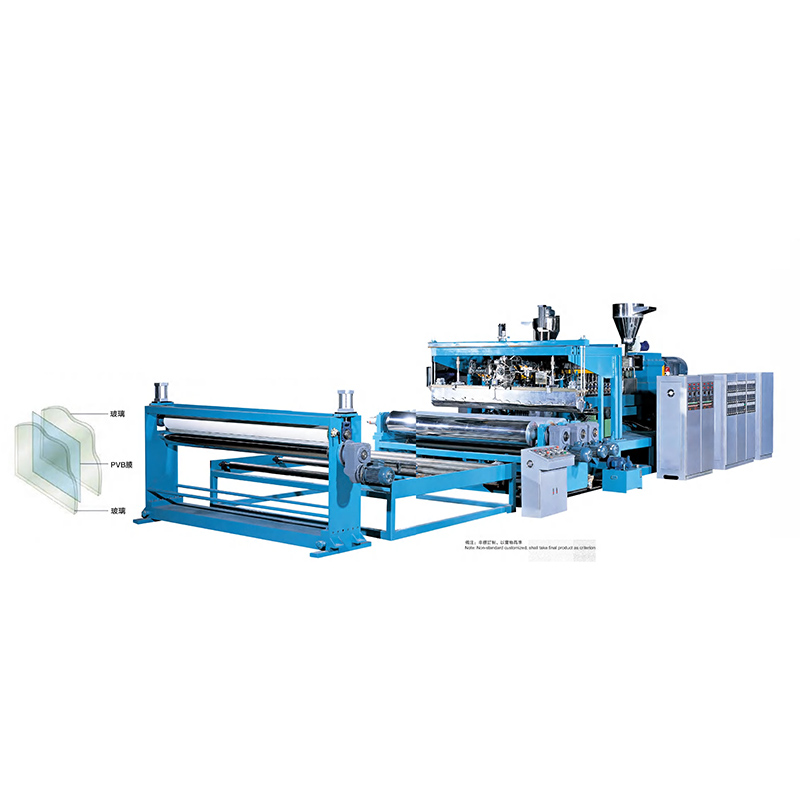

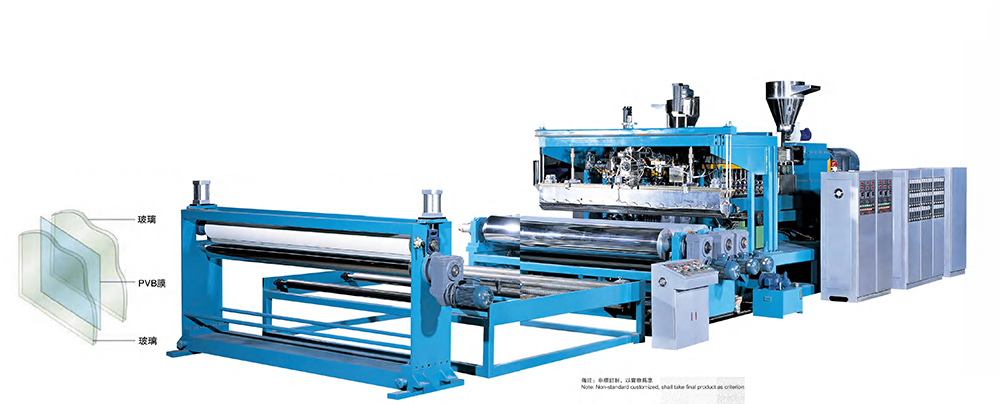

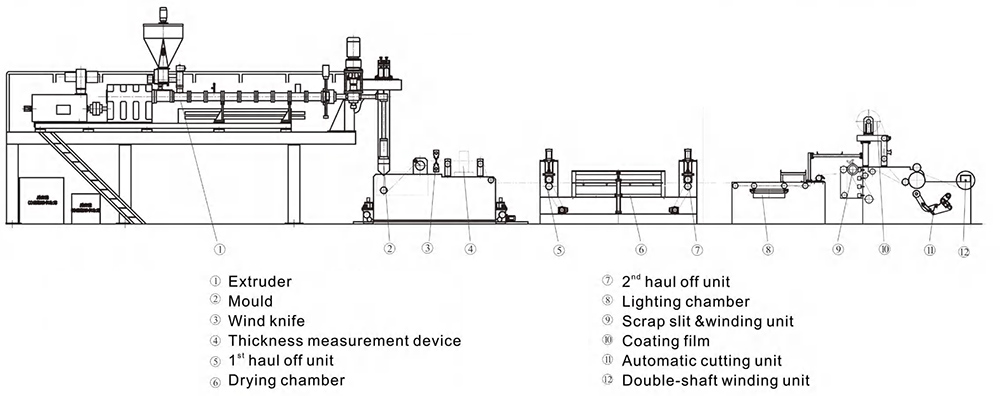

PVB glass interlayer film extrusion equipment advantage

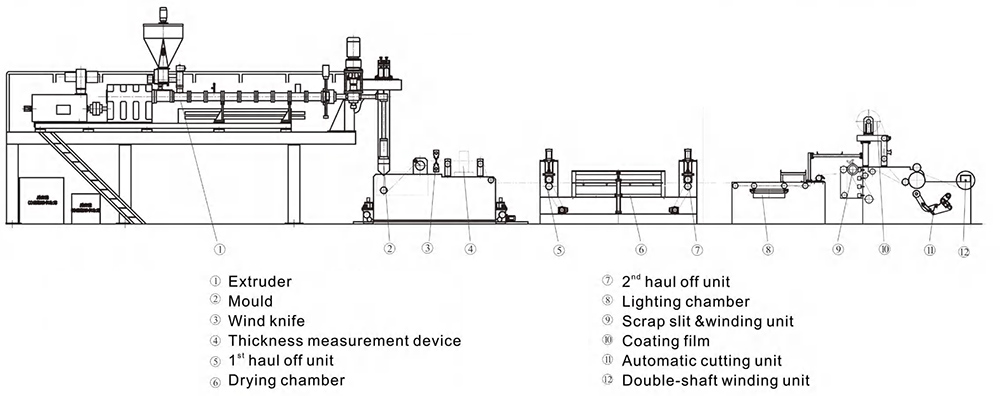

Yaoan single layer PVB interlayer film for glass lamination extrusion line for glass lamination adopts international advanced technology and special screw design, which can ensure stable and high quality extrusion according to different formulas. The advanced automatic dosing feed control ensures the superplasticized quality of extrusion. With the assistance of various devices of the machine and the feasible design of T-die, the plasticizing quality of extrusion is better. The extruder adopts automatic integrated cooling control mode, which can effectively control the melt temperature.

PVB film feature

PVB interlayer film is extruded from PVB polymer material with plasticizer DHA, and the thicknesses are usually 0.38 mm, 0.76 mm and 1.5 mm. PVB film, which is usually 0.38 mm, 0.76 mm and 1.5 mm in thickness, has good viscosity to inorganic glass, and it also has the characteristics of being transparent, heat-resistant, cold-resistant, humidity-resistant, and having high impact strength.

PVB film is the main material for making automobile windshield, because it has good safety, heat preservation, sound insulation, UV resistance and other characteristics, it is widely used in the construction field.

Quality Control

The PVB glass interlayer film extrusion equipments cannot be allowed for shipment untill the customers confirm the result of machine test with raw material. Our staff also tests machines for several hours to check whether the sizes of plastic products are according to drawings, whether the ampere of motors are stable or not, whether machine runing is steady quietly., whether the machine output is up to manufacturing orders.

Afer-sales service

We provide 100% afer-sales service. We produce plastic extruders that satisfy our customers and provide after-sales service including installation, startup operating extrusion machines, and personnel training. Customer compliments are our greatest wish.