Carrier Tape apply to the IC, SMT semiconductors, crystal and other chip components of the SMD tape packaging. Piezoelectric crystal industry specifications: 49U/SMD, 49S/SMD, UM-1/SMD, UM-5/SMD, SMU7, SMU5, osc half 8045, 7050, 6035, 5.32, 4023, 3225 and other SMT.

carrier Tape specifications:

Thickness: 0.2mm-0.5mm

Carrier tape width range: 5mm-16mmetc.

pocket size: according to client's requirement

deepth of pocket: less than 5mm

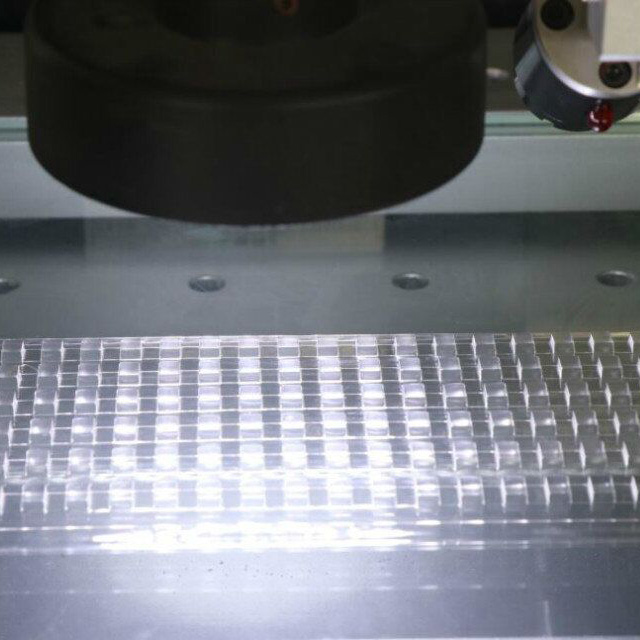

Black Conductive PS Sheet for Carrier Tape

RoHS standard

PS sheet or PC co-extrusion Sheet is black carrier tape material with good rigidity and strong toughness

Recommended for packaging of IC electronic components