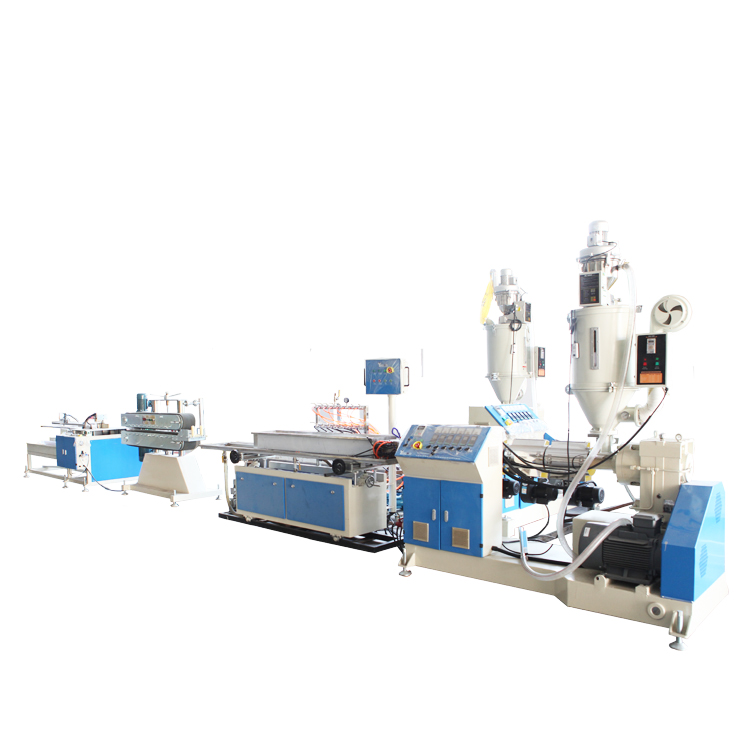

PC LED lampshade extrusion line

Raw material: Compounded granule of PC (Polycarbonate ) +diffuser powder and compounded granule of PC +white master batch

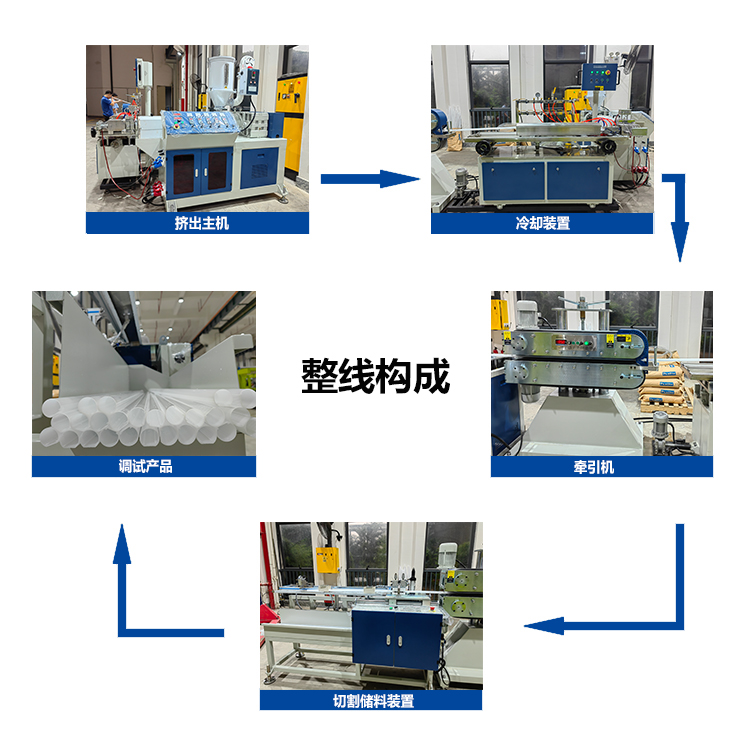

Consisting parts: Hopper dryer, vacuum laoders, extruders, die head and calibration mold, vacuum calibration water tank, belt style haul-off unit and automatic cutter.

suitable profile: T5, T8, T12 according to client's requirements

Type: Single color, double color,

Single color style machine model: AF45, AF50, AF55, AF65, AF80,

double color style machine model: AF50&45, AF55&50, AF65&AF55

Benefits of Using our PC LED Light Diffuser Profile Machine

Screw design: ensure no carbon point even after long time production

High Output: Mass production capabilities for cost-effective manufacturing.

Quality Assurance: Produces defect-free profiles with uniform light diffusion.

Versatility: Compatible with additives (e.g., anti-static or flame-retardant properties).

Brief introduction of LED Lampshade Profile Extruders

This PC led light pipe extruder automates the production of custom-designed PC diffuser profiles through an extrusion process. Key components include:

Extruder: Melts and homogenizes PC pellets.

Die/Profile Tooling: Shapes molten PC into precise cross-sectional profiles (e.g., prismatic, opal, or micro-lens designs).

Cooling System: Rapidly cools the extruded profile to retain shape and optical properties.

Haul-off/Cutting Unit: Draws and cuts profiles to specified lengths.

Key Features of the PC Led Light Profile Extruder

Precision Engineering: Ensures consistent thickness and optical quality.

Customization: Adaptable tooling for diverse profile designs (e.g., linear, curved, or textured surfaces).

Energy Efficiency: Optimized heating/cooling systems reduce energy consumption.

Automation: Integrated controls for temperature, speed, and cutting accuracy.

Why Polycarbonate?

Durability: Resistant to impact, heat, and weathering.

Light Transmission: Up to 90% clarity with minimal light loss.

Sustainability: Recyclable material aligning with eco-friendly manufacturing trends.

Applications of PC Diffuser Profiles

Architectural Lighting: Cove lighting, suspended ceilings, and façade illumination.

Automotive: Interior ambient lighting and exterior signal lights.

Commercial/Retail: Display cases, office panels, and signage.

Conclusion

PC LED Light Diffuser Profile Machines are essential for meeting the growing demand for energy-efficient, high-quality LED lighting solutions. By leveraging polycarbonate’s superior properties and advanced extrusion technology, these plastic profile extruders enable the production of durable, precision-engineered diffusers that enhance both functionality and design in modern lighting systems.