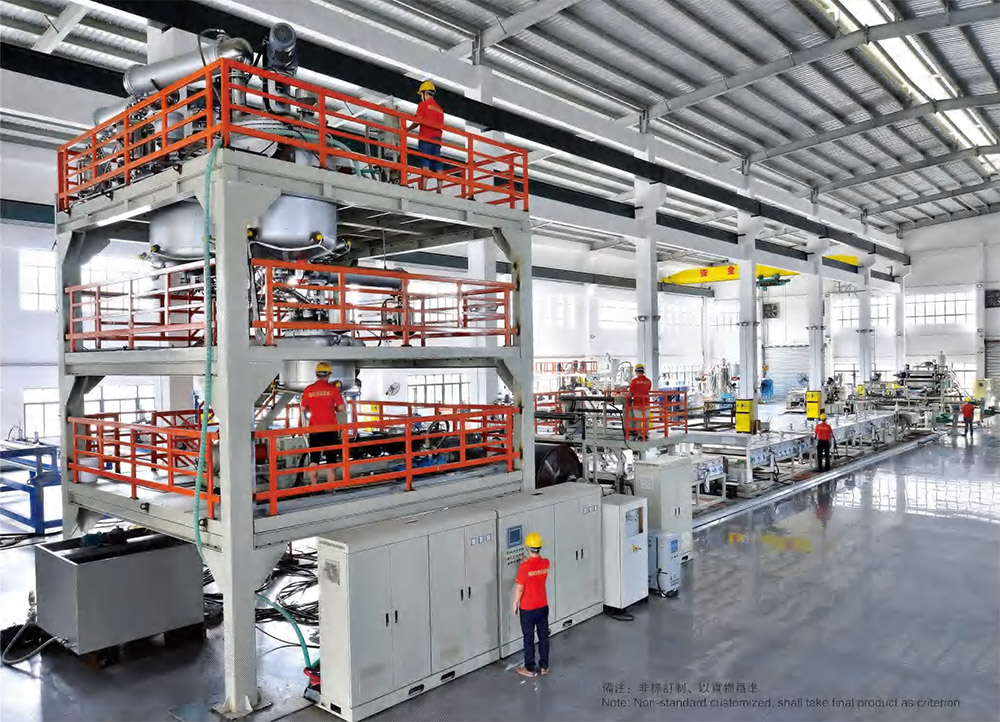

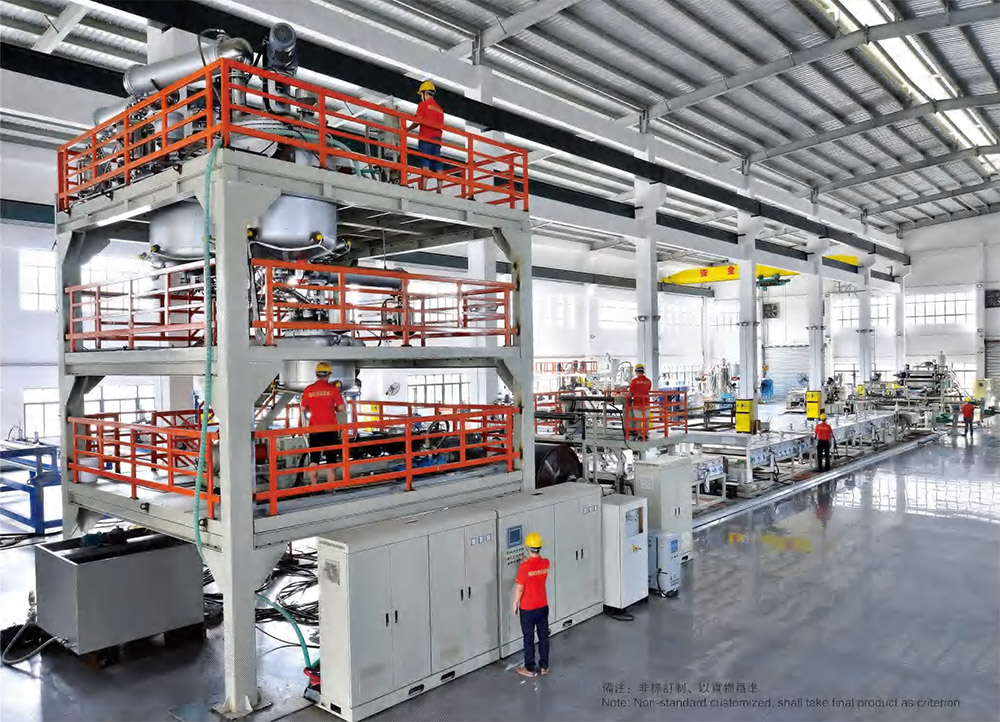

Water soluble PVA cast film extrusion line introduction

YAOAN's water-soluble PVA cast film extrusion line is a state-of-the-art solution designed for the production of high-quality water-soluble PVA film. This advanced system is characterized by its highly automated control, user-friendly operation, and consistent output with even thickness, high accuracy, excellent transparency, and glossiness. The machine has been recognized for its innovation, having obtained a patent certificate from the State Intellectual Property Office.

Key Features of YAOAN's PVA Cast Film Extrusion Line:

Highly Automated Control: Ensures precision and consistency in film production.

Easy Operation: Designed for user convenience and efficiency.

Even Thickness & High Accuracy: Guarantees uniform film quality.

Good Transparency & Glossiness: Produces films with excellent visual properties.

Quality Stability: Ensures reliable and consistent output.

Applications of PVA Film:

Washing liquid packaging

Fertilizer packaging

Water printing

And more

Film Specifications:

Process Overview:

Material Feeding: PVA material is fed into a hot reactor where it dissolves in water.

Gel Formation: The PVA solution transforms into a gel-like material.

Extrusion: The gel material is extruded through a T-die.

Drying & Forming: Water evaporates as the film flows over calender rollers and heating roller stands.

Winding: The dried PVA film is wound into rolls.

Machine Configuration:

Dissolving Reactor: Stainless steel, double-layer jacket vessel with motor-driven blending blades.

Gel Reactor: Similar structure to the dissolving reactor.

Extruder: Equipped with an anti-corrosion screw and precise temperature control.

Melt Pump: Ensures consistent flow quantity.

T-Die: Anti-corrosion design for durability.

Hot Air Device: Facilitates drying.

Calender Roller Stack: 720mm in diameter, heated by hot oil.

Haul-Off Unit: Includes hot support rollers for smooth film handling.

Automatic Winder: For efficient film winding.

Additional Option for Water Printing Process:

Advantages:

Patented Technology: Ensures innovation and reliability.

Customizable: Tailored to meet specific client requirements.

High-Quality Output: Produces films with excellent mechanical and visual properties.

Versatile Applications: Suitable for a wide range of industries.

YAOAN's PVA cast film extrusion line is a comprehensive solution for manufacturers seeking to produce high-quality water-soluble PVA films for various applications. Its advanced design, coupled with robust construction and precise control, makes it a reliable choice for industrial-scale production.

Environmental protection features of water soluble film

Water soluble film is a new type of green environmental protection material,widely used:It's a high technological content and high value added product,whether raw material selection,or processing and final consumption, it is no andwill not release any poisonous or harmful thing, is beneficial to environmental protection and green consumption,and belongs to environmentally friendly products, has a good application prospect.Water soluble film has been included in China's plastic packaging materials,"Thirteenfive-year" development plan.

Water soluble film green environmental protection technical parameters:

Film width: 800-1200mm

Film thickness: 0.03-0.07mm

Ductilityrate:10-600%

Tearing strength: 30-100kg/cm

Sealingstrength: 50kg/m

PH: 6-8

5 days bioloaical oxygen consumption: <1%

Min water content: <5%

Steam transmittance:100%

Heavy metal content: <10ppm

Safety:LD50>10000/mgkg -1no stimulation

Stability:>60℃,14 day

Our service

Our confidence comes from 40 years of accumulated experience, a large technical team of middle-aged and young people, and advanced processing equipment.

Maintain an open attitude towards customer requirements and work together with them to develop machines:

We can produce water soluble film equipments according to customer drawings and blueprints

We can work together with customers to develop new cast film machines for their special products.

Afer-sales service

We provide 100% service. We provide thoughtful pre-sales and after-sales service. We produce PVA film extrusion lines that satisfy our customers and provide after-sales service including installation, startup operating extrusion machines, and personnel training.