Double layer PVC sheet extrusion line Advantage:Film release tension is stable, product surfacesmooth and beautiful after film lamination, attachedvery well with bottom plastic.

Production width: 1000mm to 2000mm

Thickness: 0.6mm-2.0mm.

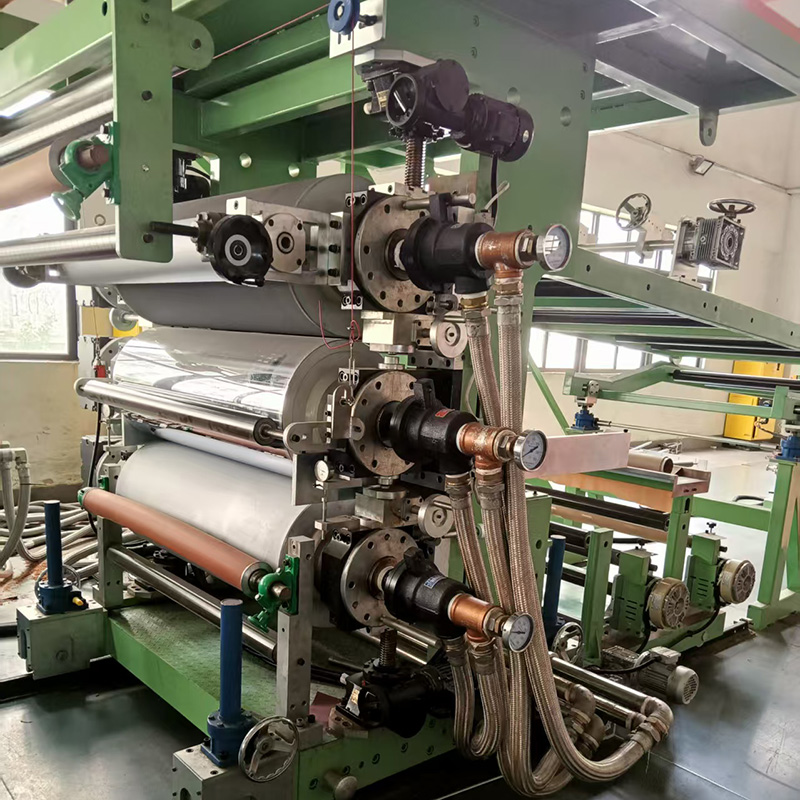

YAOAN Double Layer Flexible PVC laminated sheet extrusion machine is a highly advanced flexible PVC sheet production line designed for manufacturing double-layer PVC sheets with integrated printed designs. This machine is equipped with a printed film pay-off stand, making it ideal for producing customized PVC sheets used in packaging, floor mats, artificial leather, and other applications. Below is a detailed explanation of its features, configurations, and advantages:

Key Features of F.PVC Sheet Extrusion Machine

Double-Layer Extrusion:

Produces double-layer PVC sheets with enhanced strength, durability, and aesthetic appeal.

Allows for the integration of printed films or designs between the layers.

Printed Film Pay-Off Stand:

Equipped with two sets of pay-off stands for feeding printed films into the extrusion process.

Enables customization of the sheets with logos, patterns, or other visual elements.

Wide Production Range:

Production Width: 1000mm to 2000mm, catering to various industrial and commercial needs.

Thickness Range: 0.2mm to 3.0mm, suitable for both thin and thick sheet applications.

High Precision and Consistency:

Flexible PVC Sheets:

Machine Configuration of FLeixble PVC Carpet Sheet Extrusion Line

Two Extruders:

Designed for processing PVC granules, ensuring smooth and consistent extrusion.

One extruder for each layer, allowing for precise control over material flow.

Feed Block:

Co-Extrusion Die Head:

3-Roll Calender Roller Stack:

Printing Film Pay-Off Stand:

Air Cooling Stand:

Haul-Off Unit:

Automatic Cutter:

Applications of PVC Artifical Leather Sheet Extrusion Line

Packaging:

Floor Mats:

Artificial Leather:

Signage and Advertising:

Automotive Interiors:

Why Choose YAOAN?

Reputation and Experience:

Strong R&D Capacity:

Good After-Sales Service:

Customization:

Machines can be tailored to meet specific client requirements, including sheet width, thickness, and design.

Precision and Stability:

Global Presence:

Conclusion

The YAOAN Double Layer PVC Sheet Machine is a state-of-the-art solution for producing high-quality, flexible PVC sheets with integrated printed designs. With its double-layer extrusion capability, printed film pay-off stands, and wide production range, it is ideal for applications in packaging, floor mats, artificial leather, signage, and automotive interiors. YAOAN's advanced technology, precision control, and customization options make it a trusted choice for manufacturers seeking reliable and efficient PVC sheet production. Whether for functional or decorative purposes, this machine delivers unmatched performance and quality.

Afer-sales service

We provide 100% service. Bulk and customized small packaging, FOB, CIF, DDU and DDP.

We provide thoughtful pre-sales and after-sales service. We produce F.PVC sheet extrusion machines that satisfy our customers and provide after-sales service including installation, startup operating extrusion machines, and personnel training. Customer compliments are our greatest wish.

Packaging and Shipping

PACKAGING:plastic film + stretch film + wooden case + drying agent.

DELIVERY:About 90 days (all new parts)

SHIPPING:We place and fix the machines well into container and check carefully before closing the container so as to ensure everything is ok for the shipment. (Use steel wire to fix machine and drying agent).