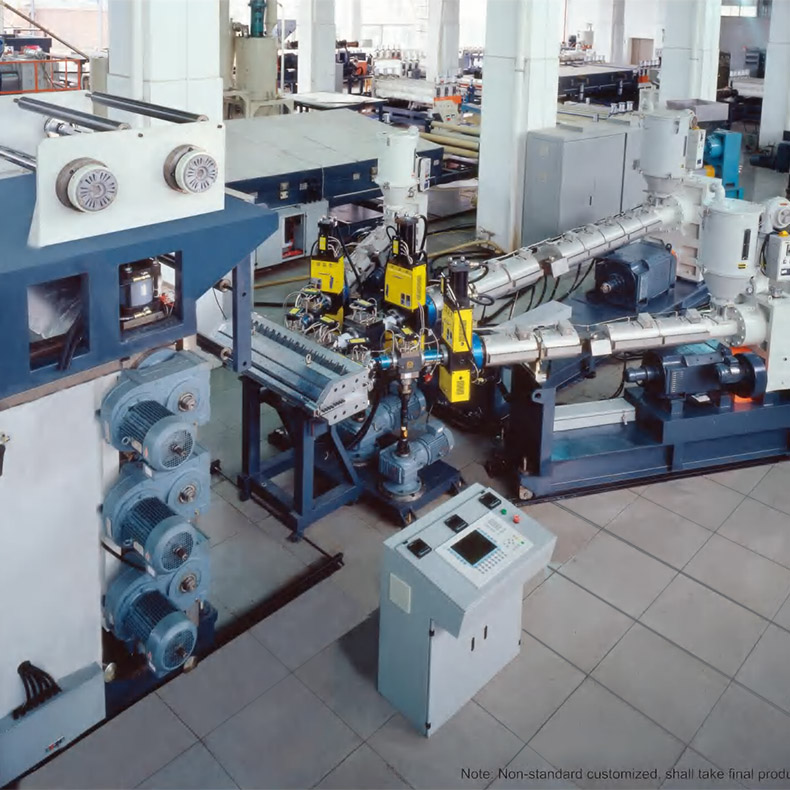

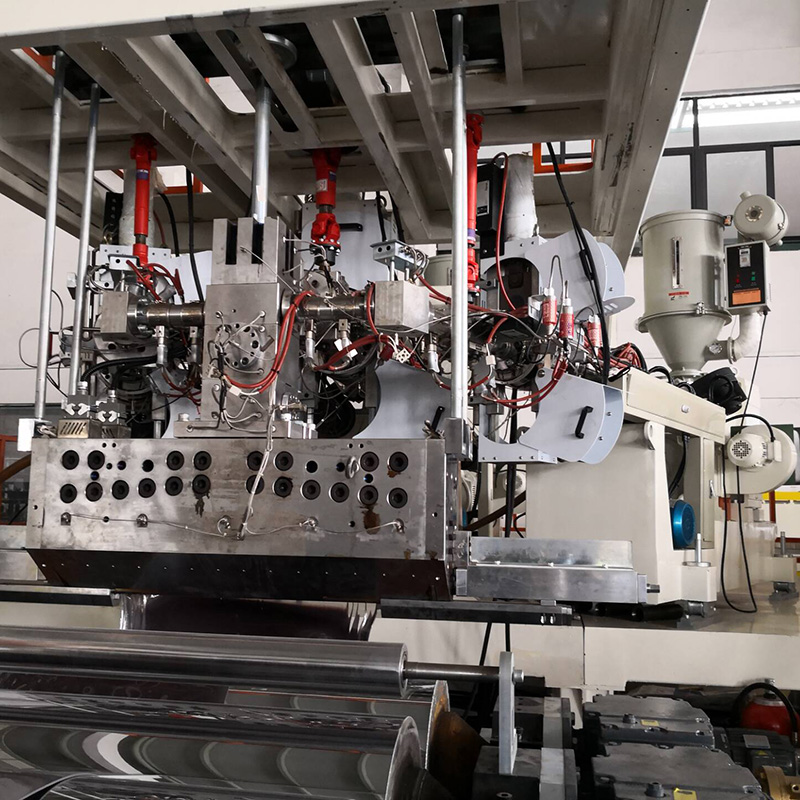

YAOAN is a leading manufacturer of high performance Multi-layer Co-extrusion Sheet Machine For PC Luggage Cases.

Our multi-layer PC luggage sheet production equipment advantages:

30 year history experience, good R&D stuff, strong and stable machine; shinning surfaces of PC sheets, strong impact resistant PC sheets; high productivity; easy operation and maintanence

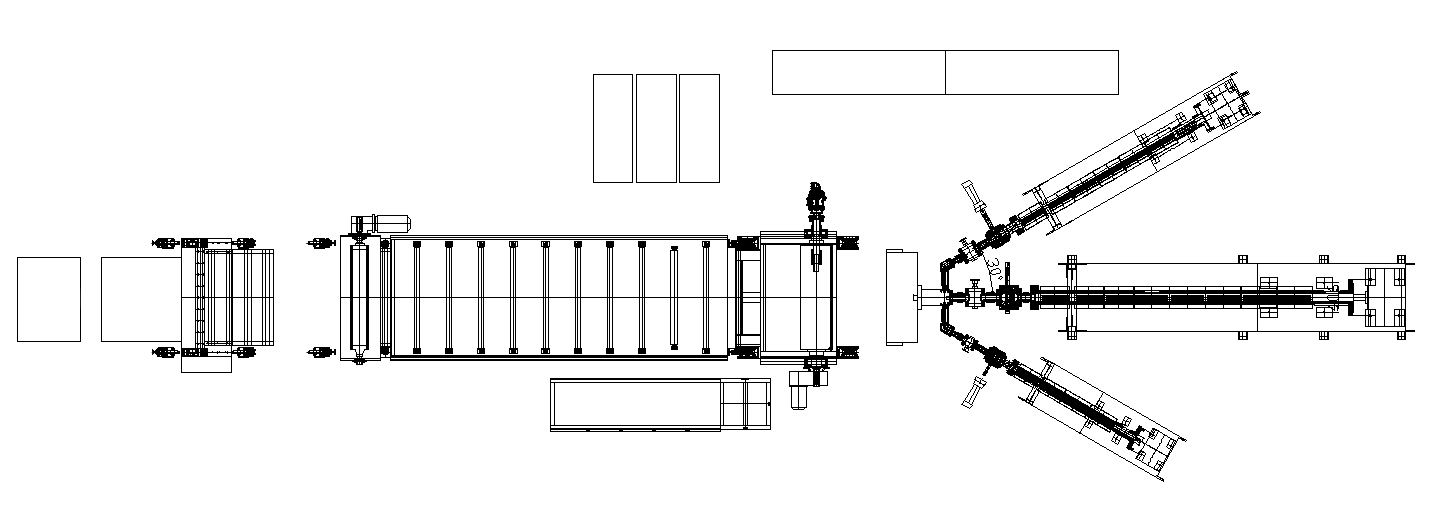

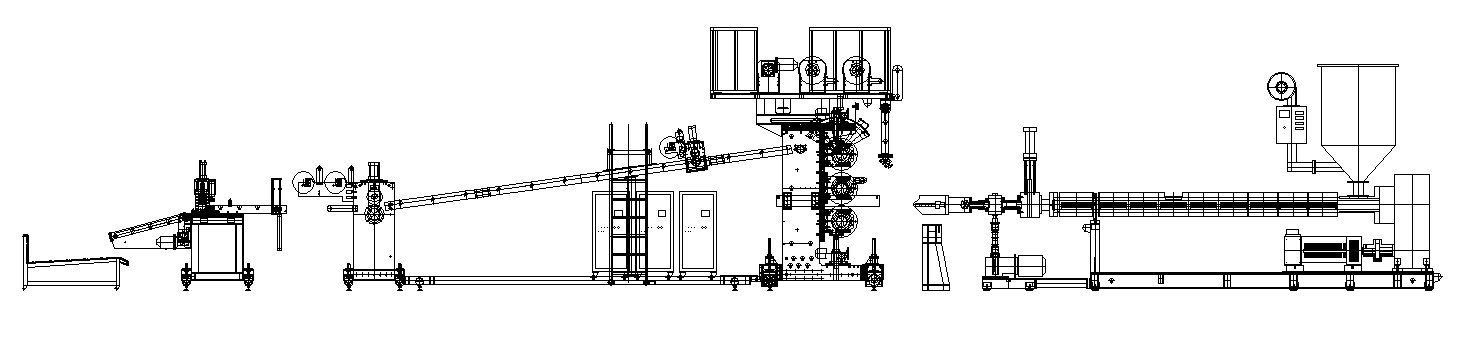

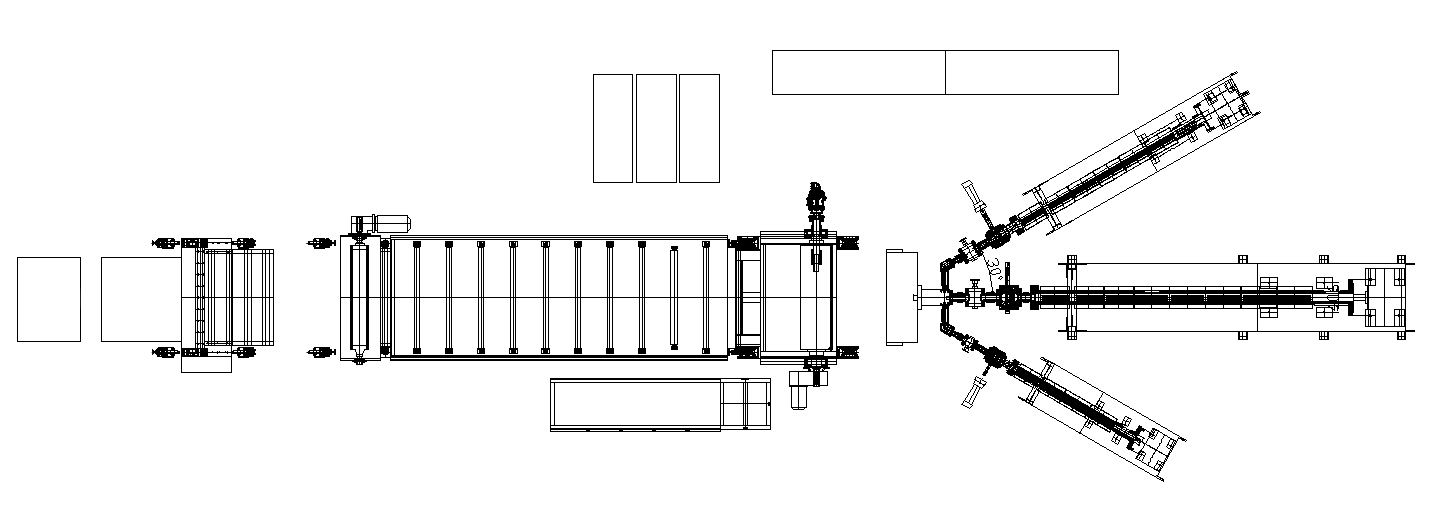

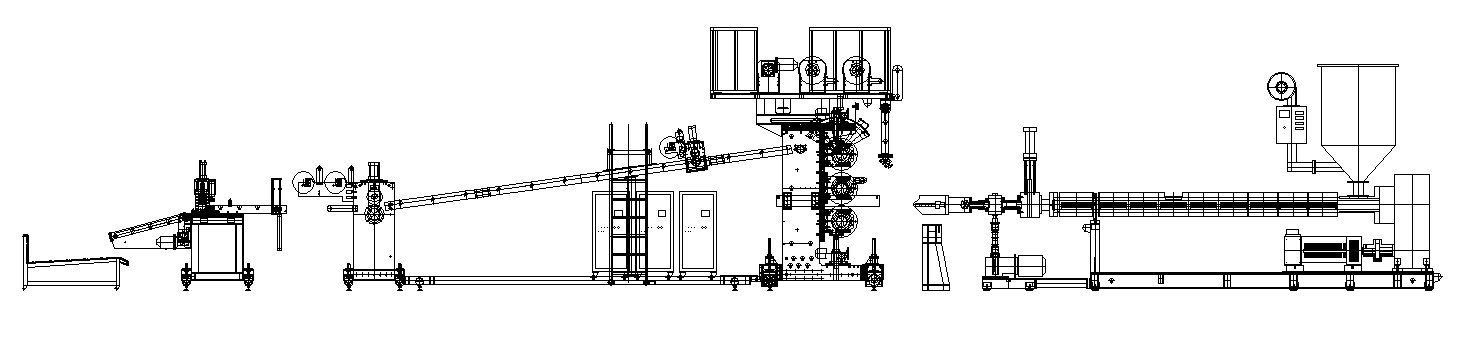

PC sheet extrusion line for PC trolley luggage consisting parts: 120mm extruder, 80mm extruder or 65mm extruder, 50mm extruder, hydraulic screen changer, melt pump, Feed block, T-die, calander roller stack, PC film pay-off stand, annealing oven, coolingstand, proctive film pay-off stand, haul-off unit, automatic cutter, accessories: such as Dehumidifier system

Customer facilities: strong floor, 0.7KG pressure compressed air, crusher, 10 tons of water/hr,

| ITEM | AF120&65 2 layer PC luggage plastic sheet extrusion line | AF120&65&65 3 Layer PC luggage plastic sheet extrusion line | AF120&80&50 4 Layer PC luggage plastic sheet extrusion line |

| sheet structure | A-B OR A-B-A A:VIRGIN PC+COLOR B:RECYCLED PC+COLOR | A-B-C OR A-B-A A:VIRGIN PC (CLEAR) B: VIRGIN PC+COLOR C:RECYCLED PC+COLOR

| A-B-C OR A-B-C-B A:VIRGIN PC (CLEAR) B: VIRGIN PC+COLOR C:RECYCLED PC+COLOR

|

| Extruder size | Layer A: 65MM extruder layer B: 120mm extruder

| Layer A: 65MM extruder layer B: 65mm extruder layer C: 120mm extruder | Layer A: 50MM extruder layer B: 80mm extruder Layer C: 120mm extruder |

| Hydrualic screen changer | 2 units | 3 units | 3 units |

| Melt pump | 2 units | 3 units | 3 units |

| Feed block and T die | 1 SET | 1 SET | 1 SET |

| Calander roller stack unit | 1 set | 1 set | 1 set |

| Oil temperature controllers | 3 units | 3 units | 3 units |

| PC film pay-off stand | 1unit | 1 unit | 1 unit |

| Cooling stand | 1 unit | 1 unit | 1 unit |

| protective film pay-off stand | 1 unit | 1 unit | 1 unit |

| Haul-off unit | 1 unit | 1 unit | 1 unit |

automatic cutter and stack table

| 1 unit | 1 unit | 1 unit |

Our supplier brands: INOVANCE(servo motor), SIEMENS(MOTOR,PLC and touch screen), ABB (inverter), GUOMAO (gear box), JC TIMES(T-die, melt pump), MAAG(MELT PUMP), SCHNEIDER(AC CONTACTORS, AIR BREAKER) ,

We can follow client's requirements of components' brand |

And we have exported more than 20 sets of PC,ABS co-extrusion luggage sheet machine to the foreign countries worldwidely. We have shipped 9 lines to SAFARI luggage company in India.

We can meet the production needs of our customers, our PC sheet extrusion line for Suit luggage cases can be designed to make ABS,PC,PS and PMMA sheets,with different special screws,mould and auxiliary equiments.The maximum effective width of sheet is 3000mm.(For PP,PE sheet,the width can be 6000mm),and thickness is ranging between 0.6-12mm.Single layer,double-layer,three-layer,four-layer and five-layer construction suit case luggage sheet extruders are available(fore-xample,AB,ABA,ABC,ABCB).