YAOAN PVC Floor Mat Sheet Machine is designed for the production of flexible PVC floor mats and sheets. Below is an introduction to its key features and specifications:

Suitable Raw Materials:

Flexible PVC powder

PVC cable sleeves

Product Specifications:

Width: 500–2500 mm

Thickness: 0.5–7 mm

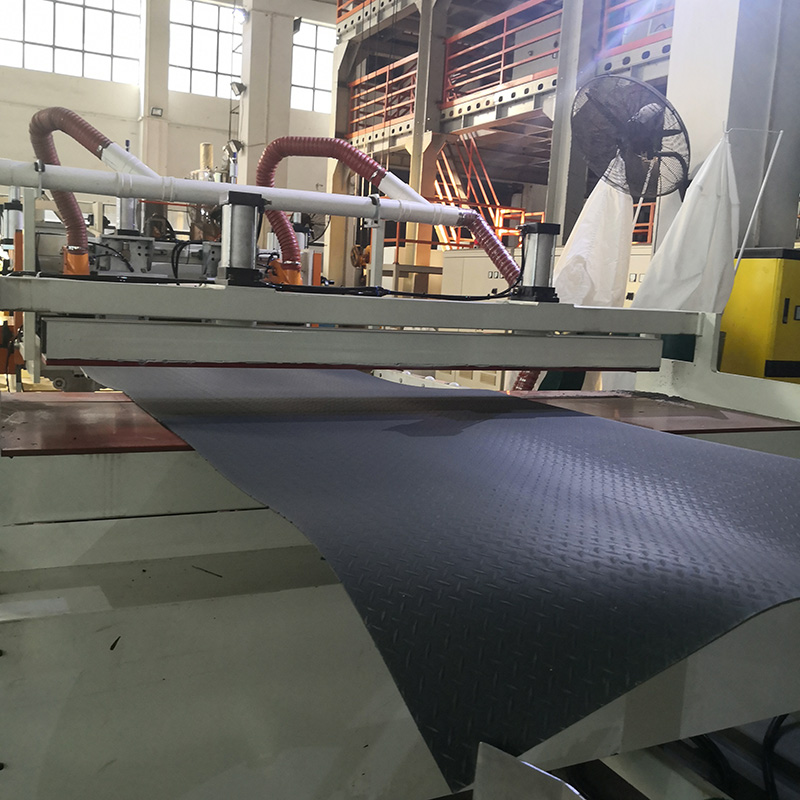

PVC Floor Mat Production Equipment Configuration:

Hot & Cold Mixer: 1 unit

Conic Twin Screw Extruder: 1 set

T-Die: 1 unit

Vertical Style Calender Roller Stack: 1 unit

Cooling Stand: 1 unit

Haul-Off Unit: 1 unit

Cutter: 1 unit

Stack Table with Robot Stacker:

This conic twin screw PVC sheet production machine is ideal for producing high-quality PVC floor mats and sheets with consistent thickness, smooth surfaces, and precise dimensions. Its automated features, such as the robot stacker, enhance production efficiency and reduce labor costs.

Our afer-sales service

We provide 100% service. Bulk and customized small packaging, FOB, CIF, DDU and DDP.

We provide thoughtful pre-sales and after-sales service. We produce medical PVC floor mat production equipment that satisfy our customers and provide after-sales service including installation, startup operating extrusion machines, and personnel training. Customer compliments are our greatest wish.

Our Quality Control

Credit Check,ISO, CE, RoSH and Supplier Capability Assessment. company has strictly quality control system and professional test lab.

we have strict quality control regulations on the inspection of spare parts. It is guaranteed by qualified staff and advanced accurate process tooling machines: 6 AXIS CNC machines, laser cutting machines, wire spare engineering machines

The PVC floor mat production equipments cannot be allowed for shipment untill the customers confirm the result of machine test with raw material. Our staff also tests machines for several hours to check whether the sizes of conic twin screw PVC sheet production machines are according to drawings, whether the ampere of motors are stable or not, whether PVC floor mat sheet machine runing is steady quietly, whether the machine output is up to manufacturing orders.